Last Revised: December 17, 2021

Revision 12/2021

Vapors from toxic and flammable chemicals can be difficult to identify and control. This Fact Sheet discusses the properties of chemical vapors, offers tips for controlling vapor exposure, and compares the hazards of common laboratory solvents.

The requirements in Penn's Chemical Hygiene Plan SOPs and Fact Sheets apply to all work involving toxic and flammable chemicals. The Fact Sheet below gives hazard information and precautions for working with volatile chemicals; however, this information is provided as a supplement to the SOPs, which must first be read and understood by anyone working with those substances in the lab.

Chemical Vapor Properties

- Chemical vapors are usually invisible to the naked eye.

- Some chemical vapors have no detectable odor even at levels that are dangerous to your health.

- Quantitative measurement of vapor concentration in the air requires professional training and equipment.

- Some chemicals must be heated before they form vapor, but other readily form vapor at room temperature (see Vapor Pressure below).

- Depending on the chemical, a vapor can be lighter than air (vapor density < 1) and rise up in the room, or it can be heavier than air (vapor density > 1) and sink towards the floor.

- Even common solvents and solutions used in the laboratory can pose significant health risks from acute (short term) or chronic (long term) exposure (see Solvent Hazards below).

- Skin and mucous membrane contact with vapor can also be a route of exposure for certain chemicals. This can lead to irritation, sensitization, and other adverse health effects.

- The vapors from flammable chemicals will ignite if there is a sufficient amount of oxygen and an ignition source present.

Hazards and Controls

The best control for limiting exposure to chemical vapor in the lab is a properly operating chemical fume hood or glove box. Point exhausts (e.g. exhaust snorkels) may be effective controls for some chemical vapors, but a risk assessment must be done to determine whether a point exhaust will be sufficient.

Keeping containers well sealed during transport and storage, cleaning spills promptly, and cleaning the outsides of containers to remove contamination will also reduce potential exposure to chemical vapor.

Tips and Tricks for Reducing Exposure to Chemical Vapor

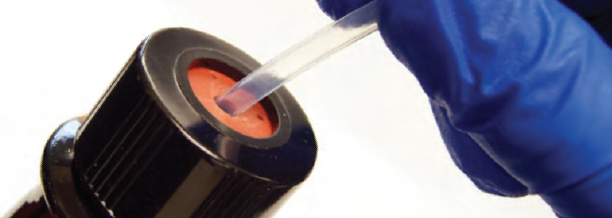

- All solvent reservoirs for instruments must have caps with a pass-through hole for the tubing (see photo 1).

- Collect hazardous volatile-liquid waste in a small container (labeled with a waste tag) inside the fume hood, then close it tightly before moving it to your lab’s satellite waste accumulation area for pick-up by EHRS.

- Keep chromatography fractions inside the fume hood as much as possible. When fractions must be outside the hood, keep them tightly covered with foil.

- Use the appropriate adapter to connect hand pumps to solvent drums (See photo 2 and photo 3). Zinc-plated solvent pumps with metal stabilizing straps are available from Sigma-Aldrich (Part: Z557803-1EA). Zinc-plated adapter rings are available to purchase separately (Part: Z557811-1EA) (See photo 3).

- Tightly cap chemical bottles and reaction vessels when moving them between fume hoods.

- Always keep waste containers tightly closed.

- Use a cold trap to condense chemical vapors evaporated from vessels under vacuum, and maintain the coolant (dry ice, liquid nitrogen, etc.) in the cold trap to ensure the vapors are fully condensed.

- EHRS recommends locating rotary evaporators (rotovaps) inside the fume hood whenever possible. If your rotovap is on the benchtop, you must evaluate the potential hazards and/or odors of the solution to determine if it is necessary to do the work inside the fume hood. Keep the solution to be evaporated and the the condenser collection flask covered during transport to reduce exposure to chemical vapors.

- Do not leave wash bottles of volatile solvents on the bench as vapor may escape, or the vapor pressure may push liquid out of the spout.

A risk assessment for chemical vapor hazards must take into account all of the following:

- Chemical health hazards and routes of exposure (e.g. Toxic if inhaled)

- Ambient temperature and/or operating temperature

- Vapor pressure (see below for an explanation of this chemical property)

- Vapor density

- Flammability

- Quantity of chemical in use

Contact EHRS for assistance with risk assessments for chemical vapor hazards.

Vapor pressure is the pressure exhibited by vapor present above a liquid surface. A higher vapor pressure value means that the chemical is more volatile and that more of the substance will be in the vapor phase at a given temperature.

- Vapor pressure increases with an increase in temperature.

- Chemicals with a vapor pressure less than 10 mmHg do not readily form vapor at room temperature.

- The temperature at which the vapor pressure of a liquid is equal to atmospheric pressure is known as the boiling point temperature.

The table below is a comparison of vapor pressure at 20 C (room temperature) for some common liquids in the laboratory. They are listed in order from least-volatile to most-volatile.

|

Chemical |

VP@20 C (mmHg) |

|

Ethylene glycol |

3.75 |

|

10% Hydrochloric Acid |

14.6 |

|

Water |

17.5 |

|

Toluene |

21 |

|

Propanol |

18 |

|

38% Hydrochloric Acid |

28.3 |

|

Ethanol |

43.7 |

|

Dichloromethane |

47.4 |

|

Formalin (37% aq. Formaldehyde) |

67 – 68 |

|

Acetonitrile |

73 |

|

Benzene |

75 |

|

Ethyl Acetate |

75 |

|

Methanol |

97.6 |

|

Hexane |

127 |

|

Acetone |

185.5 |

|

Diethyl ether |

379.6 |

The EHRS chemical Fact Sheet: Solvent Alternatives provides more recommendations for substituting common laboratory solvents with less-harmful alternatives.

The following is a comparison of the health hazards for common laboratory solvents.

This table is a reference for comparison only and does not include all of the health and safety information for each chemical. Consult the Safety Data Sheet or contact EHRS for more information about these chemicals.

Table 1: Chemical Hazard Information from Sigma-Aldrich Safety Data Sheets

|

Solvent (vapor pressure) |

Signal Word | Hazard Statement(s): | ACGIH TLV* |

|---|---|---|---|

|

Benzene (75 mmHg) |

Danger |

H225 Highly flammable liquid and vapor. H304 May be fatal if swallowed and enters airways. H315 Causes skin irritation. H319 Causes serious eye irritation. H340 May cause genetic defects. H350 May cause cancer. H372 Causes damage to organs through prolonged or repeated exposure. H412 Harmful to aquatic life with long lasting effects. |

0.5 ppm

Leukemia, Confirmed human carcinogen, Danger of cutaneous absorption |

|

Acetonitrile (73 mmHg) |

Danger |

H225 Highly flammable liquid and vapor. H302 + H312 + H332 Harmful if swallowed, in contact with skin or if inhaled. H319 Causes serious eye irritation. |

20 ppm

Lower Respiratory Tract irritation, Danger of cutaneous absorption |

|

Hexane (127 mmHg) |

Danger |

H225 Highly flammable liquid and vapor. H304 May be fatal if swallowed and enters airways. H315 Causes skin irritation. H336 May cause drowsiness or dizziness. H361 Suspected of damaging fertility or the unborn child. H373 May cause damage to organs (Nervous system) through prolonged or repeated exposure if swallowed. H411 Toxic to aquatic life with long lasting effects. |

50 ppm

Central Nervous System impairment, Eye irritation, Peripheral neuropathy, Danger of cutaneous absorption |

|

Dichloromethane (47.4 mmHg)

|

Warning |

H315 Causes skin irritation. H319 Causes serious eye irritation. H335 May cause respiratory irritation. H336 May cause drowsiness or dizziness. H351 Suspected of causing cancer. H373 May cause damage to organs (Liver, Blood) through prolonged or repeated exposure if swallowed. H373 May cause damage to organs (Central nervous system) through prolonged or repeated exposure if inhaled. |

50 ppm

Central Nervous System impairment, Carboxyhemoglobinemia, Confirmed animal carcinogen with unknown relevance to humans |

|

Methanol (97.6 mmHg) |

Danger |

H225 Highly flammable liquid and vapor. H301 + H311 + H331 Toxic if swallowed, in contact with skin or if inhaled. H370 Causes damage to organs. |

200 ppm

Headache, Nausea, Dizziness, Eye damage, Danger of cutaneous absorption |

|

Diethyl ether (379.6 mmHg) |

Danger |

H224 Extremely flammable liquid and vapor. H302 Harmful if swallowed. H336 May cause drowsiness or dizziness. |

400 ppm

Central nervous system impairment |

|

Ethyl acetate (75 mmHg) |

Danger |

H225 Highly flammable liquid and vapor. H319 Causes serious eye irritation. H336 May cause drowsiness or dizziness. |

400 ppm

Upper respiratory tract irritation, eye irritation |

|

Acetone (185.5 mmHg) |

Danger |

H225 Highly flammable liquid and vapor. H319 Causes serious eye irritation. H336 May cause drowsiness or dizziness |

500 ppm

Central Nervous System impairment, Hematologic effects, Upper Respiratory Tract irritation, Eye irritation |

*TLVs are “Threshold Limit Values”. This is the term for airborne concentration of a substance below which all workers are believed to be protected while exposed to it day after day for 8-hour periods. The numbers in the table above are provided as references for comparing relative toxicity of chemical vapors. Engineering controls and work practices must be used to reduce chemical vapor exposure to the lowest level possible, regardless of the TLV.