Last Revised: April 03, 2024

Last reviewed January 2022

Click here to return to Lab Safety Page Click here to jump to Section XVI: SOPs and Fact Sheets

The purpose of the Chemical Hygiene Plan is to acquaint students and employees with the University of Pennsylvania's safety and health policies and to inform employees of their rights and obligations under federal and state regulations. The University continually strives to provide a learning, teaching, and research environment free from recognized hazards. It is Penn's intention to improve the protection of the health and safety of students, employees and the public by providing access to information regarding the safe handling of chemicals and biological agents that are present in the workplace.

For Chemical Hygiene Plan questions or concerns, contact:

Karen Kelley, CIH, CHO

Associate Director, Industrial Hygiene and Lab Safety, Chemical Hygiene Officer

P: 267-667-2496

E: kelley@upenn.edu

Revised 3/2023

The CHP forms the foundation of the safe use of chemicals in the laboratory. It addresses chemical health and safety in Penn laboratories, and gives limited information about physical hazards commonly found in chemical research labs. The Chemical Hygiene Plan (CHP) must be available to laboratory workers, safety officers, and EHRS.

According to the US Occupational Safety & Health Administration (OSHA 29 CFR 1910.1450), federal regulations and standards, the Chemical Hygiene Plan (CHP) must include at a minimum:

- Standard operating procedures (SOPs) for each activity that uses hazardous materials. The SOPs may be generic in nature, that is, similar operations using chemicals of the same general class may be covered by one SOP.

- Criteria used to determine the risk associated with chemicals and the procedures used.

- Criteria used to determine and implement control measures to reduce laboratory workers' exposure to hazardous chemicals including engineering controls, the use of personal protective equipment, and hygiene practices. Particular attention must be given to the selection of control measures for chemicals known or suspected of being carcinogens, reproductive hazards, or acutely toxic chemicals.

- Provisions for laboratory worker training.

The Chemical Hygiene Plan applies to all laboratories at the University of Pennsylvania where hazardous chemicals are used, except those clinical laboratories located in the Hospital of the University of Pennsylvania (HUP). The hospital has its own Chemical Hygiene Plan.

The CHP is a requirement of the Occupational Safety and Health Administration regulation 29 CFR 1910.1450: “Occupational Exposure to Hazardous Chemicals in Laboratories”. This is commonly referred to as The Lab Standard.

Wherever hazardous chemicals are used in a research laboratory, a written CHP must be developed and implemented. The CHP must be capable of protecting laboratory workers and others from the health hazards associated with the hazardous chemicals used in the laboratory.

Not all chemical and physical hazard addressed by Penn’s CHP are present in every lab. The SOPs and Fact Sheets listed on your lab’s CHWP are the ones that apply to your lab’s hazards. You must read, understand, and comply with those SOPs and Fact Sheets that are listed on your lab’s CHWP.

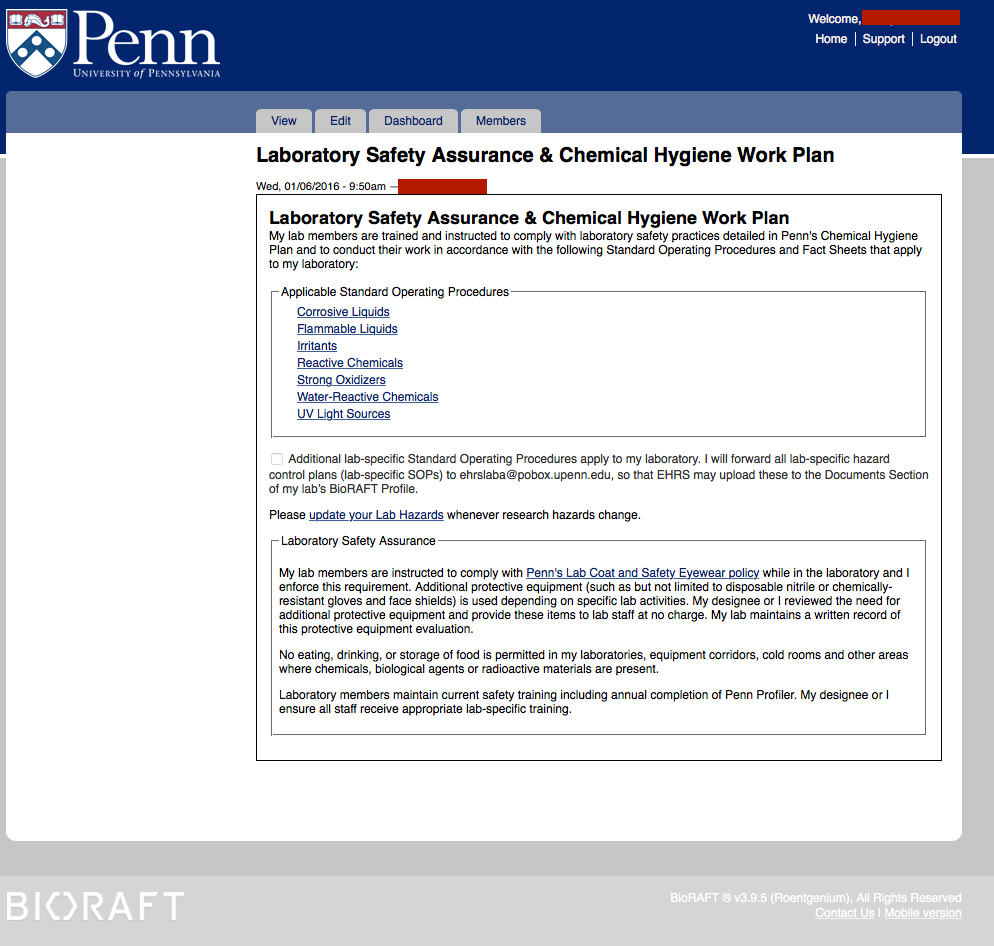

The CHWP can be found in your lab’s profile in BioRAFT.

When a PI (or delegate) completes their lab's Lab Hazard survey in BioRAFT, a Safety Assurance & Chemical Hygiene Work Plan document is automatically generated. This document contains links to any Chemical Hygiene Plan SOPs and Fact Sheets that are applicable to the lab's hazards.

When the PI certifies the CHWP, it is automatically e-mailed to all lab members listed in BioRAFT. The lab members must then read the SOPs and Fact Sheets listed on the CHWP.

The Lab Hazards must be updated in BioRAFT at least annually or whenever there are changes to the hazards in the lab. The updated CHWP must then be resubmitted by the PI.

More information about completing the Lab Hazard survey and certifying the CHWP form can be found in Appendix B.

Deans and/or department chairpersons are responsible for establishing and maintaining compliance with the CHP. To this end, deans and department chairs may wish to designate safety officers within the schools or departments. A designated safety officer should hold the rank of associate professor or full professor.

The Principal Investigator is responsible for enforcing Penn's lab safety policies. This includes:

- Creating an expectation in his or her lab that proper lab attire and personal protective equipment (PPE) will be worn, and ensuring that PPE is maintained, replaced, and/or laundered when needed.

- Confirming that all lab members have completed any required EHRS lab safety training programs, as determined by Workday Learning.

- Maintaining an up to date Chemical Inventory in Penn's online chemical inventory system.

- Providing their lab members with a copy of the CHWP and creating an expectation that the lab members must read and comply with the SOPs and Fact Sheets listed on the CHWP.

- Timely reporting of unsafe conditions or events such as equipment malfunctions, near miss incidents, injuries, or facilities issues.

The Principal Investigator must ensure that their lab members have:

- Comprehensive, lab-specific safety training

- Opportunities for guidance and mentoring about safety issues, along with other research-related issues

- Personal protective equipment, including lab coats, eye protection and disposable gloves

- Regular opportunities to bring up safety concerns and questions without fear of retaliation

Individual laboratory workers are responsible for:

- Familiarizing themselves with the Standard Operating Procedures (SOPs) and Safety Fact Sheets that are listed on their lab’s CHWP.

- Planning and conducting each operation in accordance with the CHP Standard Operating Procedures (SOPs), Fact Sheets, and any applicable Hazard Control Plans written for their lab-specific processes.

- Wearing appropriate lab attire, a lab coat, and safety glasses when working in the laboratory.

- Developing good laboratory hygiene habits such as handwashing, housekeeping, maintaining PPE in good condition, etc.

- Reporting unsafe acts, injuries, spills, and near-misses to their Principal Investigator and Environmental Health and Radiation Safety.

The Executive Director of EHRS or his/her designee shall be the University Chemical Hygiene Officer.

The Office of Environmental Health and Radiation Safety (EHRS) is responsible for working with faculty, staff, students, and others to develop and implement appropriate chemical hygiene practices and procedures. To accomplish this:

EHRS establishes procedures to:

- Monitor the procurement, use, and disposal of chemicals used in laboratory.

- Conduct laboratory chemical hygiene inspections on a periodic basis and maintain records for those inspections.

- Assist PI's in the development of Hazard Control Plans for lab-specific hazards.

- Communicate the current legal requirements for regulated substances.

The Environmental Health and Radiation Safety office (EHRS) is responsible for recommending to the Vice Provost for Research the minimum requirements of the CHP that all laboratories must follow. EHRS will review the CHP at least annually.

Biological Safety

The safe use and storage of biological organisms requires control measures similar to those found in chemical safety. See the University of Pennsylvania Biological Safety Manual for proper work practices involving biological agents.

Radiation Safety

The safe use and storage of radioactive materials require control measures similar to those found in chemical safety. However, the use of radioactive materials has additional requirements. See the University of Pennsylvania Radiation Safety User’s Guide for safe work practices involving radioactive materials.

Revised 3/2023

The Chemical Hygiene Plan (CHP) provides the background information required to establish safe working practices for chemical use and handling. The responsibility for implementation and enforcement of safe work practices is the responsibility of the principal investigator of each laboratory. The Chemical Hygiene Plan functions as both a training tool and a reference.

The Office of Environmental Health and Radiation Safety has developed Standard Operating Procedures and Safety Fact Sheets for chemical and physical hazards commonly found in University Laboratories. These SOPs specify the minimum controls for safe use of hazardous materials and equipment at the University. Adherence to the SOPs by all University of Pennsylvania lab workers is mandatory. It is the responsibility of the Principal Investigator of each laboratory to review the SOPs and ensure that the protective equipment and procedures outlined are in place. The hazard-class SOPs included in this Chemical Hygiene Plan can be found in Section XVI along with instructions for creating task-specific Hazard Control Plans when needed.

The Principal Investigator must complete the laboratory hazard assessment questionnaire in BioRAFT each year; when research conditions change; or when new hazards are introduced to the lab environment. If the task of completing the laboratory hazard assessment questionnaire was delegated to a Lab Safety Coordinator, the PI must review the list and certify that the responses are accurate. Completion of the questionnaire will automatically assign relevant SOPs and fact sheets to the lab's chemical hygiene work plan form in BioRAFT.

Lab specific SOPs must be sent to EHRS to be uploaded to the lab’s documents section in BioRAFT.

The principal investigator must digitally sign the chemical hygiene work plan, which will then be automatically emailed to all the lab members listed in the lab member list in BioRAFT. The Chemical Hygiene Work Plan in BioRAFT supersedes the paper form of the Chemical Hygiene Work Plan.

Principal investigators must ensure that all laboratory workers are provided with information and training for the hazards present in their work area. Principal investigators are also responsible for ensuring that anyone conducting research activities in their laboratory has completed the applicable EHRS lab safety training.

Training programs are developed and presented by the Office of Environmental Health & Radiation Safety (EHRS) using instructor led or web-based formats. As of March 6, 2023, Workday Learning is replacing Penn Profiler and Knowledge Link. If you have been assigned a training curriculum prior to March 3, 2023, you will not have to make new training assignments in Workday Learning.

On or after March 6, 2023, supervisors of new faculty, staff, and students will need to assign EHRS training through Workday Learning. To determine which job-related training programs you are required to assign, use the EHRS Workday Learning Selection Guide for your campus and job description. Penn employees can also self-assign courses offered by EHRS. For more information, see our Training website.

All Introduction to Laboratory Safety Training courses cover the following information about Penn’s Chemical Hygiene Plan:

- The contents of the OSHA standard 29 CFR 1910.1450 and its appendices. These are available to employees from Environmental Health and Radiation Safety and from www.osha.gov.

- The location and availability of the University of Pennsylvania's Chemical Hygiene Plan.

- The location and availability of known reference material on the hazards, safe handling, storage and disposal of hazardous chemicals found in the laboratory. This may include Safety Data Sheets and other reference sources.

- The existence of Standard Operating Procedures and Fact Sheets and their applicability to the laboratory.

- The existence of a Chemical Hygiene Work Plan and its applicability to the laboratory.

- Emergency response procedures for lab incidents.

Additional task-specific training is the responsibility of the Principal Investigator and must be as specific to the activities conducted in the laboratory as possible. It must include:

- The identity of any specific hazardous materials, equipment, or processes that the student or lab worker is expected to encounter in their research or is part of the research activities of others in the lab

- The specific health and safety risks associated with those materials, equipment, and processes

- For each hazardous material, equipment, and process: (a) The required engineering controls for safe handling and use, (b) The required work practices for safe handling and use, (c) The required personal protective equipment for safe handling and use

- The availability and location of personal protective equipment (PPE)

- Instruction on proper operation of the fume hood and other engineering controls in the lab

- The location and function of emergency irrigation equipment, fire alarms pull stations, and emergency exits

- The consequences of non-compliance with university or laboratory safety policies.

- The permissible exposure limits for OSHA regulated substances (or published exposure limits for hazardous chemicals where there is no applicable OSHA standard) for chemicals used in their lab. (available from EHRS)

- Signs and symptoms associated with exposures to hazardous chemicals used in their laboratory. (available from EHRS)

- Health risks (both chemical and physical) posed by the experimental procedures conducted in their lab.

- The existence and location of all designated areas in the laboratory.

- The selection and use of personal protective equipment appropriate for laboratory tasks. See Section XV for additional information on personal protective equipment.

Revised 10/2017

Exposure to some chemicals can result in acute or chronic health effects. Other chemicals may have properties which make them physically hazardous. It is also possible for a single substance to exhibit a combination of health hazards and physical hazards.

Various health and physical hazards of chemicals are described below.

Chemical Health Hazards

Chemical Health Hazards

Health-hazardous chemicals are chemicals for which there is statistically significant evidence (based on at least one study conducted according to established scientific principles), that acute or chronic health effects may occur in exposed employees, or if it is listed in any of the following:

- OSHA, 29 CFR 1910 Subpart Z, Toxic and Hazardous Substances

- "Threshold Limit Values for Chemical Substances and Physical Agents in the Work Environment", ACGIH (latest edition)

- "The Registry of Toxic Effects of Chemical Substances", NIOSH (latest edition)

- 29 CFR 1910.1048 Occupational Exposure to Formaldehyde

In most cases, the label will indicate if the chemical is hazardous. Look for key words like caution, hazardous, toxic, dangerous, corrosive, irritant, or carcinogen. Old containers of hazardous chemicals (pre 1985) may not contain hazard warnings.

If you are not sure that a chemical you are using is hazardous, review the Safety Data Sheet (SDS) or contact your supervisor, instructor, or the Office of Environmental Health and Radiation Safety.

The following Chemical Health Hazards are defined below:

- Irritants

- Asphyxiants

- Anesthetics

- Hepatoxins

- Nephrotoxins

- Neurotoxins

- Hematopoietic Toxins

- Inorganic Dusts

- Carcinogens

- Reproductive Hazards

- Sensitizers

- Acutely Toxic Chemicals

Chemical Toxicity

Toxicology is the study of the nature and action of poisons. Toxicity is the ability of a chemical molecule or compound to produce injury once it reaches a susceptible site in or on the body. Toxicity hazard is the probability that injury will occur considering the manner in which the substance is used.

Dose–Response Relationships

The potential toxicity (harmful action) inherent in a substance is manifest only when that substance comes in contact with a living biological system. A chemical normally thought of as "harmless" will evoke a toxic response if added to a biological system in sufficient amount. The toxic potency of a chemical is defined by the relationship between the dose (the amount) of the chemical and the response that is produced in a biological system.

Routes of Entry into the Body

There are three main routes by which hazardous chemicals enter the body:

- Absorption through the respiratory tract through inhalation. This is most important in terms of severity.

- Absorption or Injection through the skin or eyes.

- Absorption through the digestive tract through ingestion. This can occur through eating or smoking with contaminated hands or in contaminated work areas.

Most exposure standards including ACGIH Threshold Limit Values (TLVs) and OSHA Permissible Exposure Limits (PELs), are based on the inhalation route of exposure. They are normally expressed in terms of either parts per million (ppm) or milligrams per cubic meter (mg/m3) concentration in air.

If a significant route of exposure for a substance is through skin contact, the SDS will have a "skin" notation. Examples include: pesticides, carbon disulfide, phenol, carbon tetrachloride, dioxane, mercury, thallium compounds, xylene, hydrogen cyanide.

Health Effects

Acute poisoning is characterized by rapid absorption of the substance and the exposure is sudden and severe. Normally, a single large exposure is involved. Examples: carbon monoxide or cyanide poisoning.

Chronic poisoning is characterized by prolonged or repeated exposures of a duration measured in days, months or years. Symptoms may not be immediately apparent. Examples: lead or mercury poisoning and pesticide exposure.

Local refers to the site of action of an agent and means the action takes place at the point or area of contact. The site may be skin, mucous membranes, the respiratory tract, gastrointestinal system, eyes, etc. Absorption does not necessarily occur. Examples: strong acids or alkalis.

Systemic refers to a site of action other than the point of contact and presupposes absorption has taken place. For example, an inhaled material may act on the liver. Examples: arsenic affects the blood, nervous system, liver, kidneys and skin; benzene affects the bone marrow.

Cumulative poisons are characterized by materials that tend to build up in the body as a result of numerous chronic exposures. The effects are not seen until a critical body burden is reached. Examples: heavy metals.

Synergistic responses: When two or more hazardous material exposures occur the resulting effect can be greater than the effect of the individual exposures. This is called a synergistic or potentiating effect. Example: exposure to both alcohol and chlorinated solvents.

Chemicals dissolved in dimethyl sulfoxide (DMSO) pose a serious skin absorption hazard. DMSO greatly increases the transport of solute through the skin.

Other Factors Affecting Toxicity

Rate of entry and route of exposure; that is, how fast is the toxic dose delivered and by what means. Age can affect the capacity to repair tissue damage. Previous exposures can lead to tolerance, increased sensitivity or make no difference.

State of health, physical condition, and life style, can affect the toxic response. Preexisting disease can result in increased sensitivity.

Environmental factors such as temperature and pressure may also affect the exposed individual as well as host factors including genetic predisposition and the sex of the exposed individual.

Irritants

Irritants are materials that cause inflammation of the body surface with which they come in contact.

The inflammation results from concentrations far below those needed to cause corrosion.

See the Chemical Hygiene Plan SOP for Irritants for more information about health effects and safe handling practices for irritant chemicals.

Common irritants include substances such as:

- ammonia

- alkaline dusts and mists

- hydrogen chloride

- hydrogen fluoride*

- halogens

- ozone

- phosgene*

- nitrogen dioxide

- phosphorus chloride

- arsenic trichloride

* these materials also have other hazardous properties.

Irritants can also cause changes in the mechanics of respiration and lung function. These include:

- sulfur dioxide

- acetic acid

- formaldehyde*

- formic acid

- sulfuric acid

- acrolein

- halogens

* these materials also have other hazardous properties.

Long term exposure to irritants can result in increased mucous secretions and chronic bronchitis.

A primary irritant exerts no systemic toxic action, either because the products formed on the tissue of the respiratory tract are non-toxic or because the irritant action is more severe than any systemic toxic action. Example: hydrogen chloride.

A secondary irritant's effect on mucous membranes is overshadowed by a systemic effect resulting from absorption. These include:

- hydrogen sulfide

- aromatic hydrocarbons

Exposure to a secondary irritant can result in pulmonary edema, hemorrhage and tissue necrosis.

Sensitizers

A sensitizer causes a majority of the exposed population to develop an allergic reaction in normal tissue after repeated exposure to the chemical.

The reaction may be as mild as a rash (contact dermatitis) or as serious as anaphylactic shock.

Carcinogens

The term carcinogen describes any agent that can initiate or speed the development of malignant or potentially malignant tumors, malignant neoplastic proliferation of cells, or cells that possess such material.

A list of carcinogenic materials can be found in the SOP for Handling Carcinogens in this CHP.

Carcinogens commonly used in large quantities at the University include formaldehyde, benzene, ethylene amine, ethylene oxide, and chloroform.

A select carcinogen is any substance that meets one of the following criteria:

- It is regulated by OSHA as a carcinogen

- It is listed under the category, "known to be carcinogens" in the National Toxicology Program (NTP), "Annual Report of Carcinogens" (latest edition)

- It is listed under Group 1, "carcinogenic to humans" by the International Agency for Research on Cancer Monographs (IARC)

- It is listed under Group 2A or 2B by IARC or under the category "reasonably anticipated to be carcinogens" by NTP, and causes statistically significant tumor incidence in experimental animals according to any of the following criteria:

- After inhalation exposure of 6-7 hours per day, 5 days per week, for a significant portion of a lifetime, to doses of less than 10 mg/m3

- After repeated skin application of 300 mg/kg of body weight per week

- After oral doses of less than 50 mg/kg of body weight per day

Reproductive Hazards

Reproductive hazards are chemicals that affect the reproductive capabilities including chromosomal damage (mutagens) and effects on the fetus (teratogens).

See the Chemical Hygiene Plan SOP for Reproductive Hazards for more information about health effects, safe handling practices, and a list of chemicals that are hazardous to the reproductive system.

- A mutagen affects the chromosome chains of exposed cells. The effect is hereditary and becomes part of the genetic pool passed on to future generation.

- A teratogen (embryotoxic or fetotoxic agent) is an agent that interferes with normal embryonic development and may lead to birth defects or even death. Effects are not hereditary.

Toxic Chemical Classes

Hepatotoxic

Hepatotoxic agents cause damage to the liver.

These include:

- carbon tetrachloride

- tetrachloroethane

- nitrosamines

Nephrotoxins

Nephrotoxic agents damage the kidneys.

These include:

- halogenated hydrocarbons

- uranium compounds

Neurotoxins

Neurotoxic agents damage the nervous system.

The nervous system is especially sensitive to organometallic compounds and certain sulfide compounds.

These include:

- trialkyl tin compounds

- tetraethyl lead

- methyl mercury

- carbon disulfide

- organic phosphorus insecticides

- manganese

- thallium

Hematopoietic Toxins

Some toxic agents act on the blood or hematopoietic system.

The blood cells can be directly affected or the bone marrow can be damaged.

These include:

- nitrites

- aniline

- toluidine

- nitrobenzene

- benzene

Acutely Toxic Chemicals

Acutely toxic chemicals are substances falling into the following categories:

See the Chemical Hygiene Plan SOP for Acutely Toxic Chemicals for more information about health effects, safe handling practices, and a list of acutely toxic chemicals.

- A chemical that has a median lethal dose (LD50) of 50 milligrams or less per kilogram of body weight, when administered to albino rats weighing 200g to 300g each.

- A chemical that has a median lethal dose (LD50) of 2000 milligrams or less per kilogram of body weight, when administered by continuous contact for 24 hours, (or less if death occurs within 24 hours), to the bare skin of albino rabbits weighing 200g to 300g each.

- A chemical that has a median lethal concentration (LC50) in air of 200 parts per million by volume, or less, of gas, or vapor, or 2 milligrams per liter or less, of mist, fume, or dust, when administered by continuous inhalation for one hour, (or less if death occurs within one hour), to albino rats weighing 200g to 300g each.

Extremely toxic chemicals are substances that cause irreversible neurological damage or death with extremely small doses.

Substances in this class include many organic mercury compounds such as dimethyl mercury and MPTP (1-methyl-4phenyl-1, 2, 3, 6-tetrahydropyridine) which can cause irreversible Parkinsonian syndrome. Lab work with these materials requires review by EHRS and typically includes chemical resistant gloves and protective clothing.

Asphyxiants

Simple Asphyxiants deprive the tissue of oxygen. Simple asphyxiants are inert gases that displace oxygen.

These include:

- nitrogen

- nitrous oxide

- carbon dioxide

- helium

Chemical asphyxiants render the body incapable of maintaining an adequate oxygen supply.

They are active at very low concentrations (few ppm).

These include:

- carbon monoxide

- cyanides

Anesthetics

Primary anesthetics have a depressant effect upon the central nervous system, particularly the brain.

These include:

- halogenated hydrocarbons

- alcohols

Inorganic Dusts

There are toxic agents that produce damage of the pulmonary tissue (lungs) but not by immediate irritant action.

Fibrotic changes can be caused by free silica and asbestos. Other dusts can cause a restrictive disease called pneumoconiosis.

Physical Hazards of Chemicals

Physical Hazards

OSHA defines a physical hazard as a chemical for which there is scientifically valid evidence that it is a combustible liquid, a compressed gas, explosive, flammable, an organic peroxide, an oxidizer, pyrophoric, unstable (reactive), or water-reactive.

The following Physical Hazards of Chemicals are defined below:

- Combustible and Flammable Liquids

- Compressed Gases

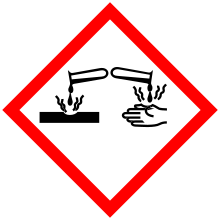

- Corrosive Chemicals

- Reactive Chemicals

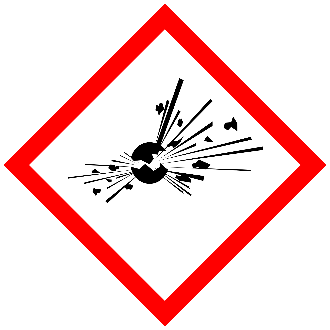

- Explosives

- Organic Peroxides

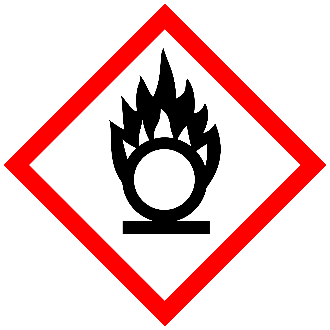

- Oxidizers

- Pyrophorics

- Water Reactives

Flammable Liquids

Flammable and combustible liquids are those liquids which can form a vapor/air mixture that is capable burning in the presence of an ignition source.

In general, flammable liquids will ignite much more easily than combustible liquids.

See the Chemical Hygiene Plan SOP for Flammable Liquids for more information about handling and storage practices for combustible and flammable liquids.

The flashpoint of a flammable liquid is the lowest temperature at which it can form an ignitable mixture with air and produce a flame when a source of ignition is present.

Combustible liquids have a flashpoint at or above 37.8°C (100°F) and below 93.3°C (200°F). Combustible liquids are divided into three classes:

| Class | Flash Point | Example |

| II | 100-139°F | Acetic acid, naptha and stoddard solvent |

| IIIA | 140-199°F | Cyclohexanol, formic acid and nitrobenzene |

| IIIB | 200°F or above | Formalin and picric acid |

Flammable liquids are chemicals that have a flash point below 100°F (38.7°C) and a vapor pressure that does not exceed 40 psig at 100°F. Flammable liquids are divided into three classes:

|

Class |

Flash Point |

Boiling Point | Example |

| IA | Below 73°F | Below 100°F | Ethyl Ether |

| IB | Below 73°F | At or above 100°F | Acetone, Benzene, Toluene |

| IC | At or above 73°F and below 100°F | Hydrazine and Styrene |

Source: National Fire Protection Association (NFPA)

Compressed Gases

All compressed gases pose a physical hazard because of the high pressures inside the cylinders.

See the Chemical Hygiene Plan SOP for Compressed Gases for more information about handling and storage practices for gases under pressure.

There have been many cases in which damaged cylinders have become uncontrolled rockets or pinwheels and have caused severe injury and damage. This danger has happened when unsecured, uncapped cylinders were knocked over causing the cylinder valve to break and high pressure gas to escape rapidly.

Poorly controlled release of compressed gas in chemical reaction systems can cause vessels to burst, create leaks in equipment or hoses, or produce runaway reactions.

Compressed gases can be either liquefied, non-liquefied, or dissolved.

[source: https://www.ccohs.ca/oshanswers/chemicals/compressed/compress.html]

Depending on the identity of the compressed gas, there may also be additional hazards such as fire, explosion, corrosion, asphyxiation, and toxicity.

Corrosive chemicals are highly reactive substances that cause obvious damage to living tissue.

See the Chemical Hygiene Plan SOP for Corrosives for more information about safe handling and storage practices.

Corrosives act either directly, by chemically destroying the part (oxidation), or indirectly by causing inflammation. Acids and bases are common corrosive materials.

Corrosive chemicals may also be referred to as "caustic", although the term caustic usually applies to strong bases.

Reactive Chemicals

The Chemical Hygiene Plan SOP Reactive Chemicals addresses the safe storage and handling of highly reactive materials which meet one or more of the following criteria:

- undergo vigorous polymerization, condensation or decomposition

- become self-reactive under conditions of shock or increase in pressure or temperature

- react vigorously with water to release a lethal gas

Many "highly reactive" chemicals are categorized as one of the following more-specific reactivity classes:

Explosive (and potentially explosive) Compounds SOP

Be sure to review the SOP or SOPs that best addresses the hazard type of your chemical. Contact EHRS if you have any questions about which requirements apply.

Explosives

An explosive is any chemical compound or mechanical mixture that, when subjected to heat, impact, friction, detonation, or other suitable initiation, undergoes rapid chemical change, evolving large volumes of highly heated gases—typically nitrogen or CO2—that exert pressure on the surrounding medium.

The term applies to materials that either detonate or deflagrate

[Source: Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards (section 4.D.3.1 Explosive Hazards) The National Academies Press: Washington, DC, 2011.]

See the Chemical Hygiene Plan SOP for Explosive Compounds for more information about safe handling and storage practices, and identifying explosives and potentially explosive compounds.

Organic Peroxides

Organic peroxides can be severe fire and explosion hazards.

An organic peroxide is any organic (carbon-containing) compound having two oxygen atoms joined together (-O-O-). This chemical group is called a "peroxy" group.

[Source: https://www.ccohs.ca/oshanswers/chemicals/organic/organic_peroxide.html]

Examples of types organic peroxides include:

- dialkyl peroxides

- hydroperoxides

- diacyl peroxides

- peroxydicarbonates

- peroxyesters

- ketone peroxides

- peroxyketals

- alkylperoxy carbonates

See the following Chemical Hygiene Plan SOPs for more information about safe handling, storage, and hazards of organic peroxides:

Depending on the identity of the organic peroxide, there may also be additional hazards such as flammability, corrosion, and toxicity.

Organic peroxides may also have a self-accelerating decomposition temperature (SADT). SADT represents the lowest temperature in which that particular organic peroxide formulation in its commercial packaging will undergo self-accelerating decomposition (begin the chemical process that leads to explosion). The SADT value will vary with each organic peroxide formulation and the size and shape of its packaging. Storage requirements will generally be 10 to 20 degrees below the SADT.

[Source: https://www.ccohs.ca/oshanswers/chemicals/organic/organic_peroxide.html]

Oxidizers

Oxidizing chemicals are materials that spontaneously evolve oxygen at room temperature (or with slight heating) or chemicals that promote combustion.

This class of chemicals includes peroxides, chlorates, perchlorates, nitrates, and permanganates. Strong oxidizers are capable of forming explosive mixtures when mixed with combustible, organic or easily oxidized materials.

See the Chemical Hygiene Plan SOP for Strong Oxidizers for more information about safe handling and storage practices. Also see the Chemical Hygiene Plan Fact Sheet for Gas-Producing Waste for special procedures for waste streams containing hydrogen peroxide and other strong oxidizers.

Examples of strong oxidizers include:

|

Ammonium perchlorate |

Ammonium permanganate |

[Source: CRC Handbook of Laboratory Safety, 3rd edition.]

Pyrophorics

OSHA defines a pyrophoric material as a liquid or solid which, even in small quantities, is liable to ignite within five minutes after coming into contact with air, at or below 55 °C (130 °F).

Many pyrophoric materials are also water-reactive, reacting vigorously with water or high humidity, often igniting upon contact.

See the Chemical Hygiene Plan SOP for Pyrophoric Chemicals for more information about safe handling and storage practices.

Examples of pyrophoric materials include:

Liquids

Organolithiums

- Alkyl and Aryl Lithiums

- n-butyllithium,

- t-butlylithium

- Lithium Amides

- Lithium Alkoxides

Organomagnesiums “Grignard Reagents”

- Alkyl and Aryl Magnesium Halides

- Methylmagnesium Chloride, Allylmagnesium Bromide

Organozincs

- Diethyl Zinc

Aluminum Alkyls

- Trimethylaluminum

- Diisobutylaluminum hydride

Metal Carbonyls

- Nickel Carbonyl

- Iron Pentacarbonyl

Silicon Halides

- Dichloromethylsilane

Solids

Metal Hydrides

- Sodium Hydride

- Potassium Hydride

- Lithium Aluminum Hydride

Finely Divided Metals

- Aluminum

- Lithium

- Magnesium

- Titanium

- Zinc

- Zirconium

- Sodium

- Potassium

Used Hydrogenation Catalysts

- Raney Nickel

- Palladium on Carbons

Gases

- Silane

- Diborane

- Phosphine

Water-Reactive Chemicals

Water-Reactive chemicals are chemicals that react vigorously with moisture.

See the Chemical Hygiene Plan SOP for Water-Reactive Chemicals for more information about safe handling and storage practices.

The most common water-reactive chemicals include sodium, potassium, lithium metals and aluminum alkyls.

Water-reactive chemicals are sometimes pyrophoric and the handling and storage procedures in the Chemical Hygiene Plan SOP for Pyrophoric Chemicals would apply.

Revised 10/2021

A label is any written, printed, or graphic material displayed on, or affixed to, containers of chemicals.

Labels or other forms of hazard warnings, such as tags or placards, provide immediate warning of potential danger. They are used to warn of a variety of potential physical hazards, or health hazards.

All hazardous chemicals throughout Penn’s campus must be properly labeled. The existing manufacturer label must not be removed, altered or defaced. If the original label must be replaced, it must contain the same information as the original label. Labels, as required by the Occupational Safety and Health Act (OSHA) Hazard Communication standard 1910.1200, must contain the following information:

- Manufacturer name, address and phone number

- Product identifier

- Signal word (“Warning”, “Danger”)

- Hazard statement(s)

- Pictogram(s) (https://www.osha.gov/Publications/HazComm_QuickCard_Pictogram.html)

- Precautionary statement(s)

Carefully read all the information on the label. If you do not understand something, contact your supervisor or instructor for an explanation or request the SDS.

This labeling requirement does not apply to students assigned unknown chemicals for analysis. However, hazard information must be provided for all unlabeled chemicals in student laboratories.

If commercially-acquired chemicals are transferred out of the original container, the new container must be labeled with the full chemical name or other non-ambiguous identifier. It is a best practice to include the date prepared and the owner's name on the label.

If a chemical container is reused to contain a different material, the original label must be removed or thoroughly defaced to avoid confusion about the contents.

Labels must be written legibly and replaced when damaged or faded.

All containers of hazardous materials 4-L or larger must be labeled with both the name and the chemical hazards.

Chemical hazard labels must be affixed to or written on any semi-permanent container of hazardous materials in the lab such as stock solutions and acid and base baths. It is highly recommended that pre-labeled bottles are purchased for solvents transferred to squeeze-type wash bottles.

Labels for laboratory containers of hazardous material can be requested from EHRS using this webform: https://ehrs.upenn.edu/health-safety/health-safety-forms/warning-sign-and-label-request-form.

If a researcher transfers hazardous chemicals from a labeled container to a portable container that is only intended for immediate use by the researcher who performs the transfer (e.g. a reaction flask or beaker), no labels are required for the portable container.

Containers of non-hazardous materials (e.g. water or buffers) must be legibly labeled with the name of all contents. Abbreviations, acronyms, and common trade names can be used if a list is posted nearby with definitions. Spills and leaks of improperly labeled, non-hazardous materials have resulted in inappropriate emergency after-hours response because the material could not be identified by first responders.

All containers of non-hazardous materials 4-L or larger must be labeled with the words “non-hazardous.” Non-hazardous labels can be requested from EHRS using this webform: https://ehrs.upenn.edu/health-safety/health-safety-forms/warning-sign-and-label-request-form.

10/26/2021, G. Allen

All containers that hold carcinogens, reproductive hazards or acutely toxic reagents must be properly labeled concerning the health hazard posed by the chemical. Most newer reagent containers will have the chemicals hazard clearly displayed on the label. However older reagents and containers of solutions that are mixed in the lab must be properly labeled by the laboratory worker.

Acid and Base Baths should be labeled with the OSHA hazard pictogram and contents. EHRS has templates for the bath labels to use with Avery UltraDuty GHS Chemical Labels 60502.

Revised 1/2022

General Guidance

Before using a chemical for the first time or when using it in novel way, review the properties of each material that will be used. Consider both the health hazards and the physical hazards of the chemical, including any reactivity or chemical incompatibility hazards. Sources of chemical safety information for particular substances include the material’s Safety Data Sheet (SDS), available from the chemical manufacturer or EHRS, and Laboratory Chemical Safety Summaries (LCSSs), available from PubChem. See the Hazardous Chemicals section of this Chemical Hygiene Plan for explanations of the various chemical hazard types. When you have identified all of the physical and chemical health hazards associated with your procedure, review the appropriate Standard Operating Procedures for each of the hazards.

For each experiment, consider the hazards that may result when chemicals are mixed together or exposed to conditions such as elevated temperature or pressure. Those conditional hazards may not be evident in the SDS or LCSS. The properties of each chemical must be considered in order to understand how it may behave during use. Resources such as Bretherick's Handbook of Reactive Chemical Hazards (available online through Penn Library) and Cameo Chemicals (free online tool) are useful resources for evaluating chemical incompatibilities and reactivity hazards.

If you are using a new chemical that introduces a novel hazard to your lab, or if the risks of working with that chemical are higher than what you would normally handle in your daily tasks, then a Hazard Control Plan must be written to describe the risks and controls for the experiment.

The following minimum guidance must be followed for all chemical handling tasks. Additional guidance for working with chemicals based on their hazard type is found in the Standard Operating Procedures:

- Minimize the quantity of hazardous chemicals that are ordered and handled in the laboratory as much as is possible.

- Substitute hazardous chemicals with less-hazardous alternatives as much as possible.

- Do not work alone in the laboratory when handling hazardous materials of any quantity.

- Wear required personal protective equipment including lab coat, safety glasses, and gloves, plus any additional protective equipment prescribed by the relevant SOP or Hazard Control Plan.

- Label all containers with the full name of all chemical contents unless you will be using the chemical immediately in your process.

- Wash hands thoroughly with soap and water after handling any chemical and whenever you leave the lab.

- Use good housekeeping practices to avoid contamination of surfaces, garments, personal belongings, and self.

- Never intentionally smell, inhale or taste a chemical.

- Smoking, drinking, eating, and the application of cosmetics is forbidden in areas where hazardous chemicals are used or stored.

- Open containers of hazardous chemicals may only be handled inside of a properly functioning fume hood unless the process has been evaluated by EHRS.

- Inspect equipment or apparatus for damage before adding a hazardous chemical. Do not use damaged equipment.

- Never use mouth suction to fill a pipette. Use a pipette bulb or another pipette-filling device. (See the Biosafety Manual for more on pipetting.)

- Promptly clean-up spills if you are able to do so safely. Contact EHRS for assistance with spill clean-up when necessary. Make sure your work space is free of chemical contamination when you are finished working.

Controlling the Risks of Chemical Hazards

The specific methods for controlling chemical hazards are described in the Standard Operating Procedures for each chemical hazard type and are further defined by the Hazard Control Plan for high hazard experiments. The following general principles of hazard control are used to determine those guidelines:

- Elimination of hazards or substitution with lower risk materials or processes

- Engineering controls protect the researcher by isolating the hazard at the source

- Administrative controls protect the researcher through work practices that lower the risks of performing the task

The controls above prevent a dangerous condition from occurring. The last level of the hierarchy of controls (PPE) prevents injury when those methods are not able to provide adequate protection.

- Personal Protective Equipment (PPE) is used as last line of defense against exposure or injury in case the other control measures are insufficent

(More information about the hierarchy of controls is available at: https://www.cdc.gov/niosh/topics/hierarchy/)

Whenever it is feasible to do so, avoid using hazardous chemicals.

When it is necessary to work with hazardous materials and processes, the following controls must be considered first:

- Substitution of a less hazardous substance

- Substitution of less hazardous equipment or process (e.g., safety cans for glass bottles)

- Isolation of the operator or the process (e.g. use of a fume hood or glove box)

When lab hazards cannot be eliminated, engineering controls should be the first type of control considered for reducing risk.

The National Institute of Occupational Safety and Health (NIOSH) defines engineering controls as a control method “designed to remove the hazard at the source, before it comes in contact with the worker. Well-designed engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection.” Engineering controls should be the first type of control considered for reducing the risks of lab hazards.

Chemical fume hoods are one example of an engineering control and these are discussed in more detail below. Other examples of engineering controls used to manage laboratory risks include:

- Blast shielding

- Glove box

- Machine guarding

- Liquid traps

- Vacuum filtration

Reducing risk through engineering controls also means selecting the equipment, apparatus, and lab ware that are appropriate for the materials and hazards of your work.

For example:

When performing small-volume liquid transfers (<10 mL) of highly hazardous materials (toxic, corrosive, or air-sensitive), it is not appropriate to use a luer-slip syringe type, because the needle can easily detach from the syringe barrel. Luer-lock or integrated-needle syringes must be used with these chemicals.

When performing larger-volume liquid transfers (>10 mL) of highly hazardous materials, a double ended needle (aka: cannula) must be used, to further reduce the risks posed by syringes, such as plunger ejection.

These are just a few examples of engineering controls. The specific methods for controlling chemical hazards are described in the Standard Operating Procedures for each chemical hazard type and are further defined by the Hazard Control Plan for high hazard experiments.

Local exhaust ventilation is one of the best engineering methods available to reduce the health hazard risk associated with the use of hazardous chemicals in the laboratory.

Fume hoods are used to prevent hazardous, offensive, or flammable gases and vapors from mixing with the general room air. A hood, especially with the sash down, also acts as a physical barrier between the laboratory workers and chemical reactions. The hood can also contain accidental spills of chemicals.

Note that laboratory fume hoods and biosafety cabinets, although similar in appearance, are extremely different devices. Biosafety cabinets are used for protection against exposure to biological materials and should not be used with chemicals unless specifically designed for this purpose. If you are uncertain about the type of hood or biosafety cabinet in your laboratory, check with your Principal Investigator or EHRS.

Check the SDS, appropriate Standard Operating Procedure, or chemical label for special ventilation requirements, such as:

- Use with adequate ventilation

- Use in a fume hood

- Avoid inhalation of vapors

- Provide local ventilation

If a fume hood is not available in your work space, contact EHRS before working with any hazardous chemicals.

To be effective, laboratory fume hoods must be installed and used correctly. The National Research Council in Prudent Practices for Handling Hazardous Chemicals in Laboratories; (1981) recommends that the following factors be remembered in the daily use of hoods:

- Hoods should be considered as backup safety devices that can contain and exhaust toxic, offensive, or flammable materials, when the design of an experiment fails. Hoods should not be used as a means for disposing of chemicals. Thus, apparatus used in hoods should be fitted with condensers, traps, or scrubbers to contain and collect waste solvents or toxic vapors or dusts.

- Hoods should be evaluated before use to ensure adequate face velocities (typically 80-100 fpm) and the absence of excessive turbulence. Further, some continuous monitoring device for adequate hood performance should be present and should be checked before each hood is used. If inadequate hood performance is suspected, it should be established that the hood is performing adequately before it is used. Call your building administrator to report inoperable hoods.

- Except when adjustments of apparatus within the hood are being made, the hood should be kept closed: vertical sashes down and horizontal sashes closed. Sliding sashes should not be removed from horizontal sliding-sash hoods. Keeping the face opening of the hood small improves the overall performance of the hood.

- The airflow pattern, and thus the performance of a hood, depends on such factors as placement of equipment in the hood, room drafts from open doors or windows, persons walking by, or even the presence of the user in front of the hood. For example, the placement of equipment in the hood can have a dramatic effect on its performance. Moving an apparatus 5-10 cm back from the front edge into the hood can reduce the vapor concentration at the user's face by 90%. Elevate large pieces of equipment 2-3 inches off of the work surface.

- Hoods are not intended for storage of chemicals. Materials stored in them should be kept to a minimum. Items stored in the hoods must not block vents or alter airflow patterns. Whenever possible, chemicals should be moved from hoods into cabinets for storage.

- Solid objects and materials (such as paper) should not be permitted to enter the exhaust ducts of hoods as they can lodge in the ducts or fans and adversely affect their operation.

- An emergency plan should always be prepared for the event of ventilation failure (power failure, for example) or other unexpected occurrence such as fire or explosion in the hood.

At Penn some hoods fume hoods are equipped with combination sashes, which include both a vertical-moving sash and also horizontal-sliding panels. These hoods are meant to be used in one of two ways:

1) With the vertical-moving sash raised to a position that is high enough to allow the researcher access to the materials in the hood, but low enough that the sash is protecting the researcher’s face and upper body.

2) With the vertical-moving sash completely down and one of the horizontal-sliding sash panels positioned directly in front of the researcher’s body. In this way, the researcher’s arms can reach around the panel to access the interior of the hood, while their entire body is shielded by the panel in front of them.

Fume Hood Inspection Program

The function of each fume hood on campus is tested upon initial installation. The velocity of the air at the face of the hood is also confirmed by EHRS annually and after any repairs are made to the fume hood fans or alarms. EHRS tests the air flow with the hood sash positioned at the height of the arrow on the green sticker along the side of the face of the hood. The hood should not be used for work with hazardous materials unless the sash is at or below this indicator. More information about the fume hood inspection program can be found on the Fume Hood website.

Reporting Fume Hood Problems

Check your hood before each use. If the alarms sounds or if you detect a problem, close your hood sash completely and re-open it no higher than the level of the arrow on the green sticker located along the side of the face of the hood.

If low-flow or no-flow is still detected and/or the alarm is sounding, follow these steps:

1) Stop all work with hazardous materials.

2) Cap all open containers in the hood and de-energize any equipment such as pumps and hot plates.

3) Contact the building administrator to request repair.

Under no conditions is it acceptable to work with hazardous materials in a fume hood that is not functioning properly. Even if you can feel/hear air flowing in the hood, you may not work in hood while the alarm is indicating low or no flow.

The building administrator will place an orange Hood Out of Order sign on the sash of the hood.

A mechanic will evaluate the hood and make the necessary repairs. Once the hood is repaired, Environmental Health and Radiation Safety will test the flow. If the hood's face velocity is adequate, the orange sign will be removed. Do not resume use of the fume hood until EHRS has confirmed adequate face velocity. Report to EHRS persistent problems with fume hoods or repair delays longer than 5 working days.

For more information on inspection and repair procedures, including building specific procedures, see Fume Hoods.

Administrative controls are work practices that reduce the risks associated with hazardous processes.

Because administrative controls rely on training and worker compliance, these methods are often used in addition to engineering controls in order to provide a higher level of risk reduction. Some examples of administrative controls in the laboratory include:

General laboratory practices such as

- Proper labeling and storage

- Good laboratory housekeeping

- Not working alone in the lab

- Testing equipment function and inspecting for damage prior to use

One example of a process-specific administrative control would be: Frequently venting a separatory funnel during a liquid-liquid extraction, and pointing the stopcock outlet away from oneself when venting.

The use of Designated Areas to segregate hazardous and non-hazardous work is also an administrative control for reducing risk of exposure or injury. See Section VI: Chemical Storage and Transportation in this CHP for more information about Designated Area requirements.

These are just a few examples of administrative controls. The specific methods for controlling chemical hazards are described in the Standard Operating Procedures for each chemical hazard type and are further defined by the Hazard Control Plan for high hazard experiments.

Personal Protective Equipment (PPE)

Revised 3/2022

If something unexpected occurs or the engineering and administrative controls are not sufficient, then the researcher's Personal Protective Equipment (PPE) provides a last line of defense against injury.

Personal Protective Equipment (PPE) is the term used for all wearable protective equipment such as safety glasses, lab coats, gloves, face shields, chemical aprons, sleeve protectors, respirators, etc.

The PI is responsible for enforcing the use of personal protective equipment in his or her laboratory.

The standard attire required in all laboratories is long pants and enclosed shoes. Shorts, skirts, sandals and other garments or footwear that leave skin exposed below the lab coat are not permitted to be worn in the laboratory.

Standard PPE for the majority of chemical handling procedures includes a 100% cotton or fire-resistant lab coat, ANSI-approved safety glasses, and minimum 4-mil-thickness disposable nitrile gloves. Lab coats made of synthetic fibers are not permitted.

Researchers who work with liquid pyrophorics, open flame, or high volumes of flammable liquids must wear fire-resistant lab coats. Contact EHRS for more information about fire-resistant lab coats.

Additional PPE may be required for some procedures. The PI is responsible for determining when additional PPE is required in his or her laboratory based on the hazards of the work. The PI must also educate lab workers on when the additional PPE is required and enforce the proper care and use of the equipment.

Safety eye wear must be worn at all times in laboratory spaces where chemical, biological, and physical hazards are present.

Eye and face protection must be worn whenever its use will reduce or eliminate injury. Eye protection must be made available to employees, students and visitors, at no cost to them, when the potential for eye injury exists.

Areas where eye protection must be worn are: laboratories, glass-cleaning and glassblowing shops, and machine shops or any area where active or automated work with chemicals is conducted. Eye protection is required for all personnel and visitors in these areas. Everyone in the room is required to wear eye protection whenever there is any chemical in use or any experimental procedure is in progress except when working at write-up station. No personnel without eye protection may enter laboratories where chemicals are being handled or automated processes are in operation.

Ordinary (street) prescription glasses do not provide adequate protection. (These glasses cannot pass the rigorous test for industrial safety glasses.) Adequate safety glasses must meet the requirements of the standard Practice for Occupational and Educational Eye and Face Protection (ANSI Z.87.1 1989) and must be equipped with side shields.

Safety glasses with side shields do not provide adequate protection from splashes, therefore, when the potential for a splash hazard exists other eye protection and/or face protection must be worn.

Splash goggles (acid goggles) with splash proof sides or a face shield must be used when protection from a liquid splash is needed.

Face shields afford protection to the face and neck. A face shield must be worn if there is an explosion or implosion (pressure or vacuum) hazard, when transferring cryogenic liquids, and in other situations where a splash, aerosol, or flying particles are likely.

Special eye protection is available for protection against laser, ultraviolet (UV), welding and brazing, or intense light sources.

Managers, supervisors, and principal investigators should refer to the Standard Operating Procedure in the Chemical Hygiene Plan for each hazard type or contact EHRS to determine the type(s) of eye and/or face protection necessary.If you have any questions regarding the selection of appropriate face protection, call Environmental Health and Radiation Safety at 215-898-4453.

Lab staff must wear lab coats at all times when handling chemicals or when working in areas where chemicals are stored or used. Lab coats must not be worn in common areas outside of the lab such as breakrooms, bathrooms, offices, and conference rooms.

Proper attire for entry into any lab where hazardous chemicals are used includes long pants or skirts that cover the entire leg and shoes that fully cover the toes and tops of the feet. Tight-fitting leggings are not recommended for the lab, as liquid chemicals that penetrate the garment will be held in direct contact with the skin.

Skin and body contact should not occur during routine lab operations that involve small quantities of laboratory chemicals. Any lab activity that is anticipated to result in body contact must be evaluated by EHRS.

Lab coats should not be worn outside of the lab. The employer (principal investigator) must provide lab coats and lab coat laundering services at no cost to all employees who work in the lab.

Lab coats for the majority of chemical handling procedures must be 100% cotton. Lab coats made of synthetic fibers are not permitted. Researchers who work with liquid pyrophorics, open flame, or high volumes of flammable liquids must wear fire-resistant lab coats. Contact EHRS for more information about fire-resistant lab coats.

Chemical protective clothing in the form of disposable work suits should be provided for the rare instances where body contact is anticipated or when extremely toxic chemicals are handled. Special attention must be given to sealing all openings in the clothing. Tape can be used for this purpose. Caps should be worn to protect hair from contamination. Selection of the protective clothing shall be made by EHRS.

Hand protection must be worn to protect against hazards of skin absorption of harmful substances, biological agents, radioactive materials, severe cuts or lacerations, severe abrasions, punctures, chemical burns, thermal burns, or harmful temperature extremes.

Chemical-Handling Gloves

Disposable nitrile gloves provide adequate protection against accidental hand contact with small quantities of most laboratory chemicals, however these gloves are not meant for protection against prolonged contact with chemicals. Lab workers who contaminate their gloves must immediately remove their gloves, wash their hands, and don new gloves. Disposable gloves may not be re-worn after they have been removed from the hands. Discard all gloves immediately after doffing.

Gloves must not be worn outside of the lab. When transporting chemicals, one glove may be worn on the hand that is carrying the secondary container, but a gloved hand must not be used on door handles or elevator buttons.

Latex gloves must not be used when working with chemicals.

More information about the selection and limitations of disposable nitrile gloves can be found in the Fact Sheet: Disposable Nitrile Gloves in Chemical Labs in this Chemical Hygiene Plan.

Lab workers should contact EHRS for advice on chemical resistant glove selection when direct or prolonged contact with hazardous chemicals is anticipated or when working with chemicals that are incompatible with nitrile. The selection of the proper glove requires knowledge of the health and physical hazards of the chemical that is used; familiarity with the glove manufacturer's test data (permeation rate and breakthrough time); and the length of the hand exposure.

Gloves for Physical-Hazard Protection

Heat-Resistant Gloves

Heat-resistant gloves have different temperature limits and intended uses. Be sure to select a glove that is designed for how you intend to use it.

Consult the glove manufacturer's product specifications or contact EHRS for assistance selecting the appropriate glove. Some examples are shown below.

Autoclave Glove

Autoclave gloves are not waterproof and should not be used for handling cryogens or dry ice. The example glove pictured is heat-resistant up to 232°C (450°F)

High-Temperature Glove

These gloves are made of cotton and have a wool liner. This material used in the example gloves pictured resists up to 2000°F (1093°C); operating temperature is 1500°F (815°C) for longer exposure. These temperatures are dependent on duration, application, and environment. Actual use temperature may be lower.

Leather Glove

Leather gloves, such as the ones shown, are generally designed for welding, and may not have a temperature rating.

Hot-glass-handling Glove

These gloves provide protection from hot glass. They may be constructed from cotton or a combination of cotton and Kevlar. The textured nitrile provides a slip-resistant surface. The heat resistance of these gloves varies. Consult manufacturer's product information.

Fire-Resistant Gloves

Lab tasks with high fire risk, such as working with pyrophoric materials or open flame, may require fire-resistant gloves that maintain good dexterity, such as Nomex pilot's gloves. You should have a Hazard Control Plan that details the required safety controls and PPE for such tasks. See also, SOP: Pyrophoric Chemicals.

Cryogen-Handling Gloves

See SOP: Cryogens and Dry Ice for information about cryogen-handling gloves.

Cut and Puncture Resistant Gloves

Puncture and cut-resistant gloves must be worn whenever there is a high risk of cut or puncture that cannot be adequately controlled through engineering and administrative controls. One example of this is when using needles that can puncture the skin and introduce an infectious agent or highly toxic substance into the body. The gloves must be rated for puncture and/or cut resistance. Do not assume that a glove is protective just because the material is thick.

Most occupational exposures do not require respiratory protection. If you think that you need a respirator contact Environmental Health & Radiation Safety. An Industrial Hygienist from EHRS will conduct a health hazard assessment to determine your potential exposure. He/She will determine if engineering controls, a change in work practices or the substitution of a less hazardous chemical can be used to reduce your exposure. If your exposure cannot be reduced, you will be provided a respirator.

If your work requires the use of a respirator, you must receive medical clearance, fit testing and training from EHRS. Never use a respirator unless you have been assigned one and have been trained and fit tested by EHRS.

Respirators are designed to protect only against specific types of substances and in certain concentration ranges, depending on the type of equipment used. Types of respiratory protective equipment include:

- Particle-removing air purifying respirators (N95, N100)

- Gas and vapor-removing air purifying respirators

- Air supplied respirators

If you would like more information about respiratory protection, please contact Valerie Perez, Industrial Hygiene Program Manager, by calling 215-898-4453 or by sending an e-mail to: Valerie Perez (vjperez@ehrs.upenn.edu).

Respirators are not to be used except in conjunction with Penn’s written respiratory protection program.

Revised 12/2020

General Considerations for Chemical Storage

Chemical storage needs must be assessed before a chemical is purchased and delivered to the laboratory. This assessment includes determining the appropriate cabinet or shelving and ensuring that sufficient space will be available. Determine chemical storage requirements by reviewing the information in this section of the Chemical Hygiene Plan and the safety data sheet for the chemical being purchased.

This section of the Chemical Hygiene Plan does not address chemical security issues. For information about securing chemicals from theft or misuse, contact EHRS.

The following general guidelines apply to all solid and liquid chemical storage areas:

- Chemicals may not be stored in the lab if:

- They have exceeded the manufacturer’s expiration date or the expiration intervals described in this section of the CHP or in any applicable SOPs.

- The container is leaking, broken, or shows signs of vapor leakage and/or chemical reaction (e.g. salt formation around cap)

- The chemical is highly hazardous and is not anticipated to be used in the next year.

All hazardous chemicals in the laboratory must be entered into Penn’s Chemical Inventory System. Information about the chemical inventory system can be found here.

All storage cabinets located in hallways and equipment corridors must be placarded with the name of the principal investigator and also with identification of the cabinet’s contents. This information is critical for emergency personnel. The lab that owns the chemical storage cabinet must complete a Chemical Storage Sign Request Form for each cabinet located in a hallway. Hazardous chemicals stored in areas outside of the laboratory must be included in the lab’s chemical inventory records (see chemical inventory section above).

Primary Storage Locations

The primary storage location for a chemical is determined by the hazards of the material. Chemical incompatibility (segregation) and chemical instability are discussed later in this section of the CHP.

Primary storage locations include:

- Refrigerator or freezer: Chemicals that must be stored at low temperature for safety or stability

- Corrosive liquids storage cabinet: Corrosive chemicals

- Flammable liquids storage cabinet: Flammable chemicals and pyrophorics

- Ventilated storage: Chemicals with strong odors and/or low odor thresholds

- Dry box or desiccator: Moisture-sensitive chemicals

- Glove box: Air-sensitive chemicals

- Open shelving or regular cabinets: Chemicals with no specified storage requirements

Chemicals that must be stored at low temperature for safety or stability can be stored in laboratory refrigerators or freezers. Flammable materials may only be stored in refrigerators/freezers if the equipment is designed for flammable material storage and UL-listed/labeled for this purpose. Contact EHRS if you are unsure whether your lab refrigerator or freezer is approved for flammable liquids storage.

Explosion-proof refrigerators/freezers are not the same as flammable-storage refrigerators/freezers. Explosion-proof devices are only required in areas where a flammable atmosphere is anticipated. In most lab situations, an explosion-proof refrigerator/freezer is not required. If you are not sure whether the model of refrigerator/freezer you wish to purchase for your lab is appropriate, please contact EHRS for guidance.

Use of household-grade refrigerators/freezers in laboratories is discouraged. Where household-grade refrigerators/freezers are used, the storage of flammable materials within them is prohibited. The refrigerator/freezer must be labeled so that it is clear that both the storage of food/drink and the storage of flammable materials are prohibited within.

When ice accumulates in a laboratory freezer, the freezer must be defrosted. The build-up of ice can cause a number of problems for chemical storage including: uneven shelf surfaces, conditions making it difficult to remove or access chemical containers, and a higher likelihood of moisture entering chemical containers. Some newer freezers are designed to prevent ice build-up, but older equipment will need to be defrosted regularly.

Hazardous chemicals must not be stored in cold rooms because cold rooms have recirculating ventilation systems. Likewise, compressed gas cylinders, liquid nitrogen dewars, and dry ice are also prohibited in cold rooms.

More information about safe use of corrosive liquids is available in the Corrosive Chemicals SOP.

Corrosive liquids must never be stored under sinks and may not be stored on shelves above eye-level.

The formation of crystals and residues around the caps of bottles of corrosive-liquids is an indication that the container is not properly sealed. Containers that show these signs of leakage must be discarded by through an EHRS chemical waste pick-up.

Inorganic corrosives

Storage cabinets that are constructed of corrosion-resistant materials are the preferred storage location for most inorganic corrosive liquids. The corrosive vapors that may escape from containers of concentrated acids and bases can damage cabinets, shelves, and brackets. This can lead to costly repairs or replacement of cabinets, and may also cause shelf failure. Thus, the storage of highly corrosive inorganic liquids in a flammable-liquids storage cabinet or in other cabinets that are not constructed of corrosion-resistant material is highly discouraged.

See the chemical segregation section below for information about the storage of acids and bases in the same cabinet.

Mildly corrosive inorganic liquids such as dilute acids and bases (1.0 N HCl or 2.0 N NaOH, for example) may be stored in open shelving. It is recommended that acids and bases stored in regular cabinets be kept on plastic trays or in plastic bins.

Amines

Amines are alkaline compounds that may be corrosive, but are generally weak bases. Amines are also commonly flammable and tend to give off strong odors. Amines do not need to be stored in a corrosion-resistant cabinet. If they are flammable, they should be kept in a flammable-liquids storage cabinet. It is usually best to store these strong-smelling chemicals in the flammable-liquids storage cabinet under the hood, as these are usually vented to the fume hood exhaust.

Organic acids and acid chlorides

Non-halogenated organic acids and acid chlorides (such as formic acid and acetic acid) are corrosive, but they are also flammable. These should be stored in a flammable-liquids storage cabinet. Keep the containers clean and tightly capped to avoid damage to the cabinet due to escaping corrosive vapor. Halogenated organic acids such as trifluoroacetic acid are non-flammable and do not need to be kept in the flammable-liquids storage cabinet.

Oxidizing acids

More information about safe use of oxidizing chemicals is available in the Strong Oxidizers SOP.

Some acids such as nitric, chromic, and sulfuric are strongly oxidizing in addition to being strongly corrosive. These acids must be kept in a corrosion-resistant cabinet and must be stored separately from all reducing agents, organic chemicals, and cellulose containing materials. Oxidizing acids must never be stored under sinks, on wooden shelves, or in wooden cabinets. They must also be kept away from paper products such as cardboard and paper towels. Strong oxidizers are highly reactive and may release hazardous gases, ignite, or form explosive mixtures on contact with wood, paper, or other organic materials.

More information about safe use of oxidizing chemicals is available in the Strong Oxidizers SOP

See “Oxidizing acids” above. This guidance applies to all strongly oxidizing chemicals.

More information about the safe use of flammable liquids is available in the Flammable Liquids SOP.

The storage of flammable and combustible liquids in a laboratory, shop, or building area must be kept to the minimum needed for research and operations. Containers one liter and larger of flammable liquids must be stored in a flammable-liquids storage cabinet. Flammable-liquids storage cabinets are not intended for the storage of compressed gases or highly corrosive chemicals. Flammable-liquids storage cabinets must meet the guidelines set forth in Lab Design & Equipment: Flammable Liquids Storage Cabinets Specifications. See also What is a Flammable Liquids Storage Cabinet?

Only compatible chemicals may be stored together inside of a single flammable-liquids storage cabinet. See “Secondary Storage Considerations: Chemical Segregation” below for details.

ChemTracker Requirements for Flammable Liquids Storage Cabinets (FLSCs)

The “Bench” location field is required for Flammable Liquids Storage Cabinets (FLSCs) in the high-rise biomedical buildings.

Flammable Liquids Storage in a Refrigerator

See “Chemical Storage in Refrigerators and Freezers” section above.

More information about the safe use of compressed gases is available in the Compressed Gases SOP and the Hazardous and Highly Toxic Gases SOP.

All compressed gas cylinders, regardless of hazard class, must be stored as follows:

- Store only the minimum amount of compressed gas required for immediate and near-term research needs. Do not stockpile gas cylinders. Promptly return unneeded gas cylinders to the vendor.

- Cylinders of hazardous compressed gases stored in common areas such as hallways must be clearly labeled with the name of the laboratory that is responsible for them.

- Cylinders must be stored in an upright position and properly secured. See Compressed Gases SOP. Compressed gas cylinders pose a crush hazard to hands and feet.

- Always use the correct regulator. Do not use a regulator adapter.

- Remove regulators when gas is not in use. If the regulator fails, the entire contents of the gas cylinder may be discharged.

- Cylinder caps must remain on the cylinder at all times unless a regulator is in place.

- Cylinders must be stored in areas where they will not become overheated. Avoid storage near radiators, areas in direct sunlight, steam pipes and heat releasing equipment such as sterilizers.

- Do not store compressed gas cylinders in cold rooms or other areas with recirculating ventilation.

- Cylinders must be segregated as described below in the “Secondary Storage Considerations: Chemical Segregation" section

- Cylinders must be transported as described below in the “Chemical Transport” section

Toxic, flammable, and oxidizing gases have additional storage requirements and limits:

- Cylinders of toxic and reactive gases must be stored and used in a fume hood or ventilated gas cabinet designed for this purpose. See the Hazardous and Highly Toxic Gases SOP for additional requirements for the storage and use of these gases. Certain gases may not be purchased and used on campus without EHRS review and approval.

The Hazard Control Plan for your lab's procedures involving pyrophoric compounds will detail any specific storage conditions and restrictions that apply to your materials.

Proper storage and transport of pyrophoric chemicals must be determined by assessing all of the hazards and physical properties of the chemical.

See SOP: Pyrophoric Chemicals for more information.

The Hazard Control Plan for your lab's procedures involving explosive compounds will detail any specific storage conditions and restrictions that apply to your materials.

Proper storage and transport of explosive chemicals must be determined by assessing all of the hazards and physical properties of the chemical.

See SOP: Explosive Compounds for more information.

Secondary Storage Considerations: Chemical Segregation