Last Revised: April 12, 2024

Revision 1/2022 (KB)

Hazard Description

For the purposes of this SOP, reactive chemicals are defined are those that may:

- undergo vigorous polymerization, condensation or decomposition

- become self-reactive under conditions of shock or increase in pressure or temperature

- react vigorously with water to release a lethal gas

Not included in the scope of this SOP

The following reactive chemical types are separate hazard classes not included in this SOP. See the SOPs linked below for more information about handling these types of hazardous chemicals.

This Chemical Hygiene Plan also includes SOPs for specific hazard classes that are considered part of the reactive-chemical hazard class. These include:

Peroxide-Formers (Class C)

Refer to those SOPs for more specific information about working with those substances.

The information below applies to the general class of highly reactive chemicals and to those types of reactive chemicals not described in other SOPs in this Chemical Hygiene Plan.

Identifying Reactive Chemicals

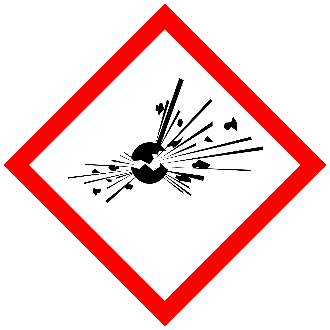

There is no GHS hazard pictogram specific to highly reactive chemicals, but depending on the specific reactivity hazard, the label will include either the explosive pictogram or the flammable pictogram.

(Type A and B)

Hazard Definitions from the Globally Harmonized System of Classification and Labeling of Chemicals (GHS)

GHS Defines the reactive chemical types as follows:

“Self-Heating Substance”

A self-heating substance is a solid or liquid substance, other than a pyrophoric substance, which, by reaction with air and without energy supply, is liable to self-heat; this substance differs from a pyrophoric substance in that it will ignite only when in large amounts (kilograms) and after long periods of time (hours or days).

“Self-reactive Substance”

Self-reactive substances are thermally unstable liquid or solid substances liable to undergo a strongly exothermic decomposition even without participation of oxygen (air). This definition excludes substances or mixtures classified under the GHS as explosive, organic peroxides or as oxidizing.

"Substances which, in contact with water, emit flammable gases"

Solid or liquid substances which, by interaction with water, are liable to become spontaneously flammable or to give off flammable gases in dangerous quantities. These are also known as "water-reactive chemicals."

“Pyrotechnic substance”

A substance or mixture of substances designed to produce an effect by heat, light, sound, gas or smoke or a combination of these as the result of non-detonative self-sustaining exothermic chemical reactions.

"Explosive substance"

A solid or liquid substance (or mixture of substances) which is in itself capable by chemical reaction of producing gas at such a temperature and pressure and at such a speed as to cause damage to the surroundings. Pyrotechnic substances are included even when they do not evolve gases.

GHS Hazard Statements

The following GHS hazard statements on a Safety Data Sheet or label would indicate that a chemical is a reactive substance.

|

Code |

Phrase |

|---|---|

|

H200 |

Unstable explosive |

|

H201 |

Explosive; mass explosion hazard |

|

H202 |

Explosive; severe projection hazard |

|

H203 |

Explosive; fire, blast or projection hazard |

|

H205 |

May mass explode in fire |

|

H206 |

Fire, blast or projection hazard: increased risk of explosion if desensitizing agent is reduced |

|

H207 |

Fire or projection hazard: increased risk of explosion if desensitizing agent is reduced |

|

H208 |

Fire hazard: increased risk of explosion if desensitizing agent is reduced |

|

H230 |

May react explosively even in the absence of air |

|

H231 |

May react explosively even in the absence of air at elevated pressure and/or temperature |

|

H240 |

Heating may cause an explosion |

|

H241 |

Heating may cause a fire or explosion |

|

H242 |

Heating may cause a fire |

|

H251 |

Self-heating; may catch fire |

|

H252 |

Self-heating in large quantities; may catch fire |

|

H260 |

In contact with water releases flammable gases which may ignite spontaneously |

|

H261 |

In contact with water releases flammable gas |

Self-Reactive Chemicals

GHS definitions divide self-reactive chemicals into types A-G. The self-reactive types that are of highest concern are A, B, C, which are defined below.

| Self-Reactive Type | Criteria |

|---|---|

| A | Any self-reactive chemical that can detonate or deflagrate rapidly, as packaged. |

| B | Any self-reactive chemical possessing explosive properties and which, as packaged, neither detonates nor deflagrates rapidly, but is liable to undergo a thermal explosion in that package. |

| C |

Any self-reactive chemical possessing explosive properties when the chemical as packaged cannot detonate or deflagrate rapidly or undergo a thermal explosion. |

The Canadian Centre for Occupational Health and Safety offers the following useful definitions for reactive chemical behaviors:

Self-Polymerization

Polymerization is a chemical reaction in which many small molecules (monomers) join together to form a large molecule (polymer). Often the reaction produces heat and pressure.

Vigorous polymerization is potentially hazardous because the reaction may get out of control. Once started, the reaction is accelerated by the heat that it produces. The uncontrolled buildup of heat and pressure can cause a fire or an explosion, or can rupture closed containers. Depending on the material, temperature increases, sunlight, ultraviolet (UV) radiation, X-rays or contact with incompatible chemicals can trigger such reactions.

Many pure substances (i.e. uninhibited) can undergo vigorous polymerization quite easily by themselves when they are heated slightly or exposed to light.

Vigorous Condensation

Condensation is a chemical reaction in which two or more molecules join together to form a new substance. Water or some other simple substance may be given off as a by-product. Some polymers, such as nylon, can be formed by condensation reactions.

Vigorous condensation can produce more energy than the surroundings can safely carry away. This could cause a fire or explosion, or rupture closed containers.

Few common pure chemicals undergo vigorous condensation by themselves. Some members of the aldehyde chemical family, including butyraldehyde and acetaldehyde, condense vigorously, but bases or sometimes strong acids must also be present. Some commercial products sold to be mixed for specialized applications may undergo vigorous condensation if they are not stored, handled and used as directed by the chemical supplier.

Vigorous Decomposition

Decomposition is a chemical change in which a molecule breaks down into simpler molecules. Vigorous decomposition is potentially hazardous because large amounts of energy can be released very quickly. This could result in a fire or explosion, or rupture a closed container causing the release of dangerous decomposition products. Some pure materials are so chemically unstable that they vigorously decompose at room temperature by themselves. For example, some organics are relatively safe only when refrigerated or diluted.

Reaction with Water to Release Deadly Gas

Some materials can react vigorously with water to rapidly produce gases which are deadly at low airborne concentrations. For example, sodium or potassium phosphide release phosphine gas when they contact water. Alkali metal cyanide salts, such as sodium or potassium cyanide, slowly release deadly hydrogen cyanide gas on contact with water. The cyanide salts of alkaline earth metals such as calcium or barium cyanide react at a faster rate with water to produce hydrogen cyanide gas. This can result in a life-threatening problem in confined spaces or poorly ventilated areas.

Large amounts of corrosive hydrogen chloride gas are rapidly released when water reacts with aluminum chloride, phosphorous trichloride, tin chloride and chlorosilane compounds. When water contacts thionyl chloride or sulphuryl chloride, they decompose rapidly giving off sulphur dioxide gas and hydrogen chloride gas. See SOP: Water-Reactive Chemicals for more information.

Approvals

A Hazard Control Plan may be required for this class of hazardous chemicals.

Contact EHRS for help evaluating whether an HCP is necessary for your lab's work with reactive chemicals.

All work with highly reactive and potentially explosive compound classes requires the approval of the P.I. The P.I. must ensure that the person or team who will be working with the hazardous material writes a task-specific Hazard Control Plan (HCP) if one required. The HCP must be sent to EHRS for review. EHRS will upload the HCP to the “documents” section of the lab’s BioRAFT page.

The P.I. must also ensure that the the person or team who will be working with the hazardous chemicals understands the hazards and has received adequate training and supervision for the procedure.

Training Requirements

No researcher may work independently with the hazardous material described in this SOP until the Principal Investigator (or their designee) has ensured that the researcher:

- Has completed all required EHRS laboratory safety training programs

- Understands the hazards of the materials and risks of the processes involved

- Has read and understands the contents of this SOP and the lab's task-specific Hazard Control Plan

- Demonstrates the ability to execute their work according to the requirements in this SOP and the lab's task-specific Hazard Control Plan

Facility Requirements

General Ventilation

Reactive chemicals may not be handled or stored in a room or facility with recirculating exhaust.

Chemical Fume Hood

All work with reactive chemicals in open or closed systems must be done in a designated area of a laboratory inside of a properly functioning chemical fume hood.

Emergency Irrigation

Emergency irrigation (safety shower, eyewash) must be accessible within a 10-second travel distance of the area where the work is performed.

Signage and Labeling

A legible manufacturer’s label including hazard information must be present on all commercial containers of reactive chemicals.

If commercially purchased reactive chemicals are transferred to another container for storage or to make stock solutions for later use, special labeling requirements apply. See the “Researcher-Created Labels” section in Section IV: Chemical Container Labeling in this CHP for a complete list of requirements.

See the SOP for Explosive Compounds for labeling requirements pertaining to potentially explosive compounds synthesized in the lab.

Date Containers

Write on the container label the date that a reactive commercial material was received and the date the container was opened.

Storage and Transport

Proper storage and transport of reactive chemicals must be determined by assessing all of the hazards and physical properties of the chemical.

See Section VI: Chemical Storage and Transportation in this CHP for a complete list of requirements.

Storage guidance specific to reactive chemicals is given below. (These guidelines are excerpted from National Research Council (US) Committee on Prudent Practices in the Laboratory. Washington (DC): National Academies Press (US); 2011. (Section 5.E.7. Storing Highly Reactive Substances))

- Consider the storage requirements of each highly reactive chemical prior to bringing it into the laboratory.

- Consult the SDS in making decisions about storage of highly reactive chemicals.

- Bring into the laboratory only the quantities of material needed for immediate purposes (<3- to 6-month supply, depending on the nature and sensitivity of the materials).

- Label, date, and inventory all highly reactive materials as soon as received.

- Do not open a container of highly reactive material that is past its expiration date. Call EHRS (215-898-4453) for advice on how to dispose of reactive materials that are past expiration.

- Store highly reactive liquids in trays large enough to hold the contents of the bottles.

- Store materials that react vigorously with water away from possible contact with water.

- Store thermally unstable materials in a refrigerator approved for the storage of flammable chemicals.

- Store liquid organic peroxides at the lowest possible temperature consistent with the solubility or freezing point. Liquid peroxides are particularly sensitive during phase changes. Follow the manufacturer's guidelines for storage of these highly hazardous materials.

- Potassium will form peroxides and superoxides when stored under oil at room temperature. Do not keep solid potassium metal in the lab for more than three years.

- Segregate the following materials:

|

Concerning Inhibitors

(Inhibitor information from The Canadian Centre for Occupational Health and Safety )

An inhibitor is a chemical that is added to a material to slow down or prevent an unwanted reaction such as polymerization. Inhibitors are added to many materials that can polymerize easily when they are pure.

Inhibitor levels in materials may gradually decrease during storage even at recommended temperatures. At storage temperatures higher than recommended, inhibitor levels can decrease at a much faster rate. At temperatures lower than recommended, the inhibitors may separate out. This action can result in some part of the material having little or no inhibitor.

Some inhibitors need oxygen to work effectively. Chemical suppliers may recommend checking oxygen and inhibitor levels regularly in stored materials and adding more if levels are too low.

Vapors from inhibited materials do not contain inhibitors. If these vapors condense and form polymers, they can block vents or flame arrestors in process equipment or containers.

Hazard Controls

The Hazard Control Plan for your lab's procedures involving reactive compounds will detail specific engineering controls, work practices, or personal protective equipment that is required.

Some general guidance is given below.

Engineering Controls

Chemical Fume Hood

All work with reactive chemicals in open or closed systems must be done in a designated area of a laboratory inside of a properly functioning chemical fume hood or glove box.

The fume hood is designed to capture chemical vapor and the hood sash acts as a shield in case of chemical splash. The sash must be kept closed as much as feasible.

Blast Shield

A portable blast shield may be placed in front of a vessel containing reactive material. This provides additional protection in the case of an explosion. Your lab's task-specific Hazard Control Plan will specify whether a blast shield is required for your process.

Vacuum Protection

Mechanical vacuum pumps must be protected using cold traps and, where appropriate, must include a filter to prevent particulate release. The pump exhaust must be vented into an approved exhaust duct or chemical fume hood.

Glove Box

Certain reactive chemicals must be handled in a glove box rather than a fume hood. The Office of Environmental Health and Radiation Safety (8-4453) or the Principal Investigator will determine if this is required.

If a chemical fume hood or glove box is not available, contact EHRS to determine whether the risks can be adequately controlled using alternative controls.

Work Practices

A list of recommended work practices for hazardous chemical handling is included in Section V: Chemical Handling in this CHP. Be sure to consult related SOPs and Fact Sheets for the specific type of reactive material you are using. Below is some general guidance for reactive chemical use:

Considerations for purchase

- Do not use reactive chemicals if less-hazardous alternatives are possible.

- Purchase, dispense, and use the smallest quantity of reactive chemicals possible.

- Purchase the lowest concentration of reactive chemicals that will meet your research needs.

- Purchase reactive chemicals that include inhibitors when such products are available. Inhibitors are added to products to slow down or prevent an unwanted reaction such as polymerization

Considerations for work space

- Work with reactive compounds in areas that you've designated especially for this work.

- Post a sign on the fume hood when a process involving potentially reactive compounds is unoccupied. A template is available for download: Unattended Operations Sign Template

- Remove all other chemicals and hazardous materials from the work area.

- Be aware of nearby processes and other conditions that may effect the stability of the reactive chemicals. Examples are adjacent sources of heat or light, which may increase the likelihood of uncontrolled chemical reactions.

Considerations for handling

- Do not handle reactive chemicals when working alone.

- Notify other lab occupants when you work with reactive compounds is in progress.

- Immediately close all containers of reactive chemicals after use and return them to their designated storage location.

- Dilution decreases the potential for explosive chain reactions.

- Never return excess chemicals to the original container. Small amounts of impurities may be introduced into the container that may cause a fire or explosion.

- Avoid the use of metal spatulas and needles when working with compounds for which metal ions may catalyze explosive decomposition reactions.

- Avoid the use of ground-glass joints when working with compounds for which friction or mechanical shock may trigger explosion.

- Explosive reactions are often triggered by one of the following conditions or events: Heat, Impact, Friction, Catalysts, or Light. Avoid any of these conditions that may trigger the class of compound you are working with.

Additional work practices for reducing the risks of any lab procedure involving reactive chemicals must be described in a written Hazard Control Plan.

Personal Protective Equipment

Consider the potential routes of exposure and health consequences when selecting personal protective equipment (PPE) for tasks involving reactive chemicals.

In addition to the minimum lab apparel and PPE requirements, other protective equipment may be necessary to reduce risks. When additional equipment (such as tight-fitting chemical splash goggles, chemical-resistant gloves, or disposable lab coats) are required, a Hazard Control Plan must be written to document the risk assessment and controls.

Contact EHRS for assistance with risk assessments, glove compatibility, and other PPE selection.

The minimum PPE requirements for all chemical handling tasks, and information about specialty PPE can be found in the "Personal Protective Equipment" section of Section V: Chemical Handling in this CHP.

Waste and Decontamination

The Hazard Control Plan for your lab's procedures involving reactive compounds will detail specific procedures for spills, decontamination of surfaces, and collection of hazardous waste.

Some general guidance is given below.

- Wash hands thoroughly with soap and water after handling any chemical and whenever you leave the lab.

- Use good housekeeping practices to avoid contamination of surfaces, garments, personal belongings, and self.

- Decontaminate all surfaces that have come in contact with reactive chemicals and clean-up small spills promptly. See the chemical Safety Data Sheet or contact EHRS for assistance with determining an appropriate decontamination method. See “Spills” below for instruction on what to do in the event of a large or hazardous spill of an reactive chemical.

|

If you find a reactive chemical container that is damaged, bulging, past-expiration, leaking or otherwise compromised in any way, do not handle the container. Move away from the area and prevent others from entering the area. Contact EHRS immediately by calling 215-898-4453. |

See the page Disposal of Highly Reactive Reagents for guidance on how to dispose of unused or expired highly reactive chemicals.

For complete hazardous waste guidelines, see the waste section of the EHRS website: Laboratory Chemical Waste Management Guidelines

Emergencies

Emergency Contacts

General emergency response information can be found at Emergency Info

Spills

General procedures for chemicals spill response can be found in Section X: Chemical Spills in this CHP.

Do not hesitate to call EHRS for assistance with spill cleanup for reactive materials.

24 hours: 215-898-4453

Contact Penn Police (511) only if the spill involves a fire, imminent risk of fire, an injury requiring an ambulance, or if there is a hazard that may affect others in the building.

List of Reactive Chemicals

The following are reactive chemical types and examples that may be found in a research laboratory. This is not a comprehensive list of all reactive chemicals. Consult the SDS for each chemical to determine the hazards.

Self-polymerizing

- acrylic acid

- acrylonitrile

- cyclopentadiene

- diketene

- ethyl acrylate

- hydrocyanic acid

- methacrylic acid

- methyl acrylate

- vinyl acetate

Self-reactive under conditions of mechanical shock, increased temperature, or increased pressure

- ammonium perchlorate

- azo and diazo compounds

- acetylides

- azides

- fulminates

- hydrogen peroxide solutions (91% by weight)

- many organic peroxides

- nitro and nitroso compounds

- nitrate esters

- perchloric acid solutions (over 72.5% by weight)

- picric acid

- picrate salts

- triazines

- some epoxy compounds

Examples of Chemical Groups Indicating Self-Reactive Properties in Organic Material

|

Structural feature |

Examples |

|---|---|

|

Mutually reactive groups |

Aminonitriles, haloanilines, organic salts of oxidizing acids |

|

S=O |

Sulphonyl halides, sulphonyl cyanides, sulphonyl hydrozines |

|

P-O |

Phosphites |

|

Strained rings

|

Epoxides, aziridines |

|

Unsaturation |

Olefines, cyanates |

References

This SOP was based on the previous version of EHRS SOP for Reactive Liquids and Reactive Solids and the following additional resources:

- https://www.ccohs.ca/oshanswers/chemicals/reactive/react.html

- https://www.osha.gov/dsg/hazcom/docs/ghsoshacomparison.pdf

- https://pubchem.ncbi.nlm.nih.gov/ghs/