Last Revised: September 20, 2023

Revision 1/2022

Definitions

Cryogen

A liquid cryogen is a liquefied gas with a boiling point typically below 123 K (-150°C). The most common cryogens used at the Penn are liquid nitrogen and liquid helium.

Dewar

A dewar is an insulated container used to store and transport liquefied gases. It is insulated by a vacuum between its two walls and is equipped with pressure relief device(s).

A cryogen dewar can be at atmospheric pressure, such as those used for sample storage, or it may be a pressurized vessel used for delivering liquid cryogen or gas.

See the fact sheet Intro to Cryogen Dewars for more information about the design and function of pressurized liquid-cryogen dewars.

Dry Ice

Dry ice is frozen carbon dioxide. Dry ice sublimates from a solid to a gas at temperatures above -78.5°C (atmospheric pressure).

Pressure-relief devices

Pressure-relief devices are devices that relieve pressure from cryogenic systems. These devices may be:

(1) valves which open to relieve pressure

(2) bursting discs that break to relieve pressure and must be replaced or

(3) loose-fitting lids on Dewar flasks.

Some pressure-relief devices vent intermittently under normal conditions, while others are emergency relief devices.

Hazard Description

The following hazards are associated with the storage, handling, and transport of cryogenic liquids and dry ice. See the Hazard Controls section of this document to learn how to lower the risks of these hazards.

- Burns

- Asphyxiation

- Fire hazards

- Formation of liquid oxygen

- Pressure hazards

- Facility damage

Burns

Even brief skin contact with a cryogen, dry ice or non-insulated equipment parts can cause cold burn and frostbite. Prolonged contact can result in blood clots. Eye contact with a cryogen or dry ice can cause permanent damage.

Asphyxiation

Although the gases created by the evaporation of most cryogenic liquids and dry ice are non-toxic and non-reactive, they will displace oxygen in the room and create an oxygen deficient atmosphere, which may result in death.

|

Remember: You cannot detect an oxygen deficiency or over-exposure to carbon dioxide unless there is an oxygen-monitoring device installed in the room. The inert gases are odorless and colorless. By the time you realize you are being deprived of oxygen, it may be too late! |

A quench (the loss of superconductivity followed by the rapid release of gaseous cryogens) of an NMR or other cryogen-cooled magnet can result in an oxygen deficient atmosphere. The volumetric expansion rate from the liquid to gaseous phase ranges between 690 to 750 times.

The use of dry ice in cold rooms can cause increased breathing, headache, dizziness, nausea and visual disturbances due to elevated carbon dioxide concentrations in the air. Dry ice can also cause asphyxiation in confined spaces.

Pressurized liquid-cryogen dewars are equipped with pressure-relief devices that regularly vent gas under normal conditions to maintain a safe internal pressure. Storing dewars in a confined space or in a room with inadequate ventilation increases the potential for creating an oxygen-deficient atmosphere. This can occur even when liquid nitrogen is not being dispensed or used.

Fire hazards

The most common cryogenic liquids used in laboratories (liquid nitrogen and helium) are not flammable. Some liquid cryogens such as hydrogen, however, are flammable or reactive in their gaseous form. The use of liquid hydrogen requires prior approval from EHRS.

Formation of liquid oxygen

All liquid cryogens with boiling points below -183°C (including liqui d nitrogen and liquid helium) are capable of condensing air to liquid. When air condenses, the nitrogen component of the liquefied air will evaporate first, leaving behind highly reactive and potentially explosive liquefied oxygen.

d nitrogen and liquid helium) are capable of condensing air to liquid. When air condenses, the nitrogen component of the liquefied air will evaporate first, leaving behind highly reactive and potentially explosive liquefied oxygen.

Liquid oxygen is a pale blue color.

See the “Hazard Controls” section below for more information.

Vacuum-jacketed system and over-pressurization hazards

A dewar has an insulating vacuum space in between its double walls. If a dewar becomes damaged, air or liquid can leak into the vacuum space. This will reduce its insulating properties and can greatly increase the pressure inside the dewar.

Dewars and storage vessels are equipped with pressure-relief devices that prevent high pressure from developing (liquid nitrogen dewars have one valve and one bursting disc; liquid helium dewars have two valves and one disc, dewar flasks are equipped with loose-fitting lids or specially vented stoppers.)

Air or liquid that leaks into a vacuum space can freeze. If the space is rapidly warmed after starting a transfer, the pressure-relief valve will vent the gas that is generated, preventing an explosion.

Cyrotubes stored in liquid nitrogen may “explode” when removed from the dewar:

Cyrotubes are not guaranteed to be leak tight if stored in liquid nitrogen. Because of the “super fluidity” of liquid nitrogen, it can leak into sealed cyrotubes. When removed from the dewar, the liquid nitrogen that leaked into the cryotube expands causing the tube to “explode”.

Property Damage

Cryogens can damage rubber tubing and crack floor tiles if spilled. Special care should be taken to avoid spilling any cryogens. Cracked floor tiles may also present a tripping hazard to other workers. Notify your Building Administrator of any floor tiles that require repair.

Do not dispose of dry ice or liquid cryogens in the sink or floor drains, as this will cause damage. Allow cryogens to evapoerate/sublime in an open container in a well ventilated space.

Approvals

EHRS evaluation and approval is required for any new equipment installation that requires the storage or handling cryogenic liquids except when the equipment is replacement-in-kind.

Depending on the process and cryogen volumes, ventilation studies, a written risk assessment, oxygen monitoring devices, and/or a Hazard Control Plan may be required. EHRS will advise you on what the requirements are for your proposed equipment or process.

EHRS must also approve the purchase and installation of any oxygen monitoring devices.

The use of liquid hydrogen requires approval from EHRS.

Training Requirements

No researcher may work independently with the hazardous material described in this SOP until the Principal Investigator (or their designee) has ensured that the researcher:

- Has completed all required EHRS laboratory safety training programs

- Understands the hazards of the materials and risks of the processes involved

- Has read and understands the contents of this SOP

- Demonstrates the ability to execute their work according to the requirements in this SOP

Facility Requirements

General Ventilation

Cryogens may not be handled or stored in a room or facility with recirculating exhaust such as cold rooms, warm rooms. Cryogens may not be handled or stored in enclosed spaces such as closets or anterooms that are not actively ventilated.

Hazard Controls

Engineering Controls

Prevent over-pressurization of dewars

- Cryogenic systems must be equipped with pressure-relief devices. Never use a system that does not have pressure-relief devices in place.

- If you purchase a new Dewar that will be filled at Penn’s liquid nitrogen filling station in the Anatomy-Chemistry building purchase a high pressure tank (235 psi) equipped with a dual pressure (22/150 psig) relief valve system.

Prevent Spills/Splashes/Burns

- Only fill a dewar from a transfer line that has a phase separator attached to the end of the line. Phase separators separate gas from liquid, preventing an overabundance of gas from surrounding the end of the transfer line and allowing only liquid nitrogen to fall into the dewar. Place the phase separator so that it rests on the bottom of the dewar.

- Use stainless steel tubing to transfer cyrogens. Never use rubber or plastic tubing. The temperature can cause rubber or plastic tubing to become brittle and crack, spraying the liquid onto surrounding surfaces. Liquid helium must be transferred through a vacuum-insulated tube because of its extremely low heat of vaporization.

- Use appropriate glassware rated for use with cryogens.

Prevent Asphyxiation due to Oxygen Displacement

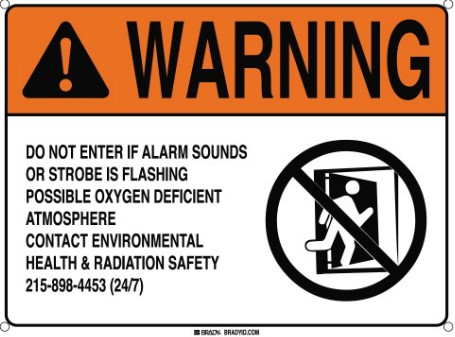

- Oxygen monitoring devices with alarms and/or strobes are installed in some areas where liquid cryogens are stored and used. EHRS will conduct a hazard assessment to determine whether oxygen monitoring is required.

Work Practices

Prevent Asphyxiation

- Store or dispense liquid cryogens only in rooms that have been approved for this work. Small, enclosed spaces and rooms with inadequate air exchange pose a high risk of asphyxiation when working with cryogens.

- Do not work alone when handling cyrogens.

- Never lower your head inside a dry ice chest or cooler. Carbon dioxide is heavier than air.

Prevent Spills/Splashes/Burns

- Use polypropylene vials rated for cryogenic use that have a silicone O-ring and internally threaded caps.

- Avoid overfilling cryotubes.

- Never use a pressurized dewar that is malfunctioning or in need of repair. Never use tools (like wrenches) to operate valves on dewars. If the valves do not opearate by hand, the equipment requires maintenance and must not be used.

- Remove all metal jewelry from wrists and hands (a spill/splash could freeze the jewelry to your skin).

- Inspect cryogen gloves prior to use to ensure that there are no holes.

- Never use a funnel when dispensing liquid cryogen into a dewar. The funnel can freeze, creating a splash hazard.

- Never fill a dewar or storage vessel if the tubing is damaged.

- Never over-fill a dewar. This may cause liquid nitrogen to leak into the cryotubes stored in the dewar. Upon removal from the dewar, cryotubes may explode when the liquid inside is warmed and expands.

- Never leave a fill process unattended.

- When cooling objects with liquid cryogens, lower them very slowly into the liquid using tongs to prevent boiling and splashing.

- Where possible, only store cryogenic vials in the vapor phase above the liquefied gas, not in the liquid phase.

- Use a mechanical device such a forceps to handle samples.

- Use a CryoClaw to retrieve samples that have fallen into a dewar. (CryoClaw available from Fisher Scientific; Catalog # 11-675-95).

- Thaw vials in a thick-walled container (i.e. desiccator with lid) or within a fume hood or biosafety cabinet.

Prevent Fire

- The use of isopropyl alcohol in dry ice baths is preferred over the use of acetone, as isopropyl alcohol is less flammable.

Prevent Formation of Liquid Oxygen (Explosion Hazard)

Liquid oxygen forms when a cryogen-cooled cold trap is opened to the atmosphere while the trap is still cold. This condition is especially dangerous because the combination of liquid oxygen and organic substances in the trap can form explosive mixtures.

The correct order of operations for venting a cryogen-cooled cold trap is as follows: (Source: Prudent Practices)

- Isolate the trap from the source of the vapor being condensed.

- Remove the trap from the liquid nitrogen bath and allow it to warm.

- Vent the trap to atmospheric pressure in the fume hood.

It’s worth noting that condensed oxygen does not readily reach hazardous concentrations directly in the coolant bath or inside of dewars of liquid nitrogen. Furthermore, there is less likely to be organic solvents present inside the bath or dewar, thus, the risk of forming explosive mixtures is much lower.

| Never vent cold trap system to air or turn off vacuum when any portion of system is at liquid nitrogen temperature |

See Emergency Procedures section of this document for instructions on what to do if liquid oxygen forms.

Prevent over-pressurization of dewars

- Do not store or transport cryogens in air-tight containers.

- Never remove, plug, or modify a pressure relief device or any other part of a cryogen dewar.

- Never cover a pressure relief valve that is venting.

Personal Protective Equipment

Laboratory personnel must always wear safety glasses and lab coats when working with cryogens, dry ice or around dispensing lines where cold burns may occur.

The following PPE must be worn when filling dewars or removing specimens or samples from a dewar:

- Cryo-gloves

- Face shield

- Safety glasses

- Lab coat

- Long Pants

- Enclosed shoes

The following must be worn when handling dry ice:

- Cyro gloves

- Lab Coat

- Long Pants

Cryogen Gloves are available from Fisher Scientific; Catalog # 11-394-305.

Cryo-gloves only provide short-term protection against accidental skin exposures and are not designed to protect skin against prolonged contact.

Cryo-gloves only provide short-term protection against accidental skin exposures and are not designed to protect skin against prolonged contact.

Other types of gloves such as nitrile, leather, heat-resistant, or autoclave gloves do not provide adequate protection for any duration of contact with cryogens.

Signage and Labeling

Label all cryogen containers with a cryogen warning and the cryogen’s name.

Storage and Transport

Always work with cryogens and dry ice in well ventilated spaces especially when filling dewars. If you are working in a small space, open a door to increase ventilation. Do not work with or store dry ice in cold rooms.

Always use a dewar or storage vessel rated for the cryogen you are refilling or transporting. Do not use Styrofoam containers or thermos bottles for holding or transporting liquid cyrogens. Never put cryogens in a sealed container. It will rupture as the material vaporizes.

Always use an appropriate wheeled cart to transport a dewar or storage vessel. Never pull, push or roll a dewar or storage vessel.

Training and special packaging is required when shipping samples on dry ice. See: Shipping Dangerous Goods.

Waste Disposal

Do not dispose of dry ice or liquid cryogens in the sink or floor drains, as this will cause damage. Allow cryogens to evaporate/sublime in an open container in a well ventilated space.

Emergencies

General Emergency Response Information is found at Emergency Info.

Cryogen Burns/Skin Contact

If skin comes in contact with a cryogen or dry ice, run the area of skin under cool or warm water for fifteen minutes (do not use hot or cold water).

If your finger is burned do not place it in your mouth. This could burn your mouth.

Do not rub the area; rubbing can cause further tissue damage.

Notify your supervisor and proceed immediately to Occupational Medicine or Student Health, accordingly.

Uncontrolled Pressurized-Dewar Venting

Occasional venting of a pressure-relief device is part of the normal operation of pressurized cryogen dewars. Sometimes a relief valve will fail or freeze open and venting will occur continuously.

If a tank is venting continuously, leave the area and contact EHRS. Prevent others from entering the area until the oxygen concentration in the room can be measured.

Leaking Tank

If a liquid-dispensing valve is damaged or is not closed properly after use, it may freeze open, and liquid will leak from the valve or transfer hose. Ice buildup around the valve or hose will be evident.

If you discover a leaking cryogen tank, contact EHRS.

Formation of Liquid Oxygen

If you find a light blue liquid in your cryogen-cooled trap, take precautions to shield yourself from the trap using a portable blast shield or hood sash.

When in doubt, close the sash, notify others in the area, and leave the lab.

Call EHRS immediately.

If liquid oxygen begins to warm up while the system is closed (not vented), the expanding oxygen will over-pressurize the system.

The appropriate steps for safe release of condensed oxygen are as follows:

- Use a hood sash or other shielding to protect yourself.

- Contact EHRS and the PI of your lab to report the condition.

- Inform those around you of the hazard and advise them to keep clear.

- Remove the liquid nitrogen dewar that is cooling the trap.

- Immediately open the trap to vent it to atmosphere.

- Keep shielding in place around the trap and leave the lab. Ensure that no one else enters the lab.

- Check back in 20-30 mins to see if the liquid oxygen has evaporated.

- If it has not evaporated, leave and check back periodically until it has.

- After the oxygen has evaporated it is safe to resume work.

Oxygen alarms

Oxygen monitoring devices with alarms and/or strobes are installed in some areas where liquid cryogens are stored and used. The doors to these room are posted with a sign explaining what to do in case of alarm.

If the alarm sounds when you are in the space, leave immediately and contact EHRS (215-898-4453) 24/7.

If the alarm is sounding when you are outside the door, do not enter under any circumstances. Call EHRS (215-898-4453) 24/7.

Cryogen Spill

Do not attempt to clean up a spilled cryogen. If a large volume of gas is released, leave the area immediately and call EHRS (215-898-4453) 24/7.

Related SOPs and Fact Sheets

References

This SOP was based on the document “EHRS Safety Fact Sheet for Cryogens & Dry Ice” and the following additional resources:

- National Research Council. 2011. Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards, Updated Version. Washington, DC: The National Academies Press. doi:https://doi.org/10.17226/12654.

- OSHA QuickFacts Laboratory Safety Cryogens and Dry Ice

- http://www.chemistryviews.org/details/education/3728881/Tips_and_Tricks_for_the_Lab_Air-Sensitive_Techniques_1.html